Exploring Techniques in the Construction of Felt Fabric for Creative Projects

Understanding Felt Fabric Construction

Felt fabric has been an essential material in a variety of applications, ranging from fashion to industry. It is unique in its construction compared to other fabrics, offering distinctive properties that make it ideal for various uses. This article delves into the intricacies of felt fabric construction, exploring its composition, manufacturing processes, and advantages.

What is Felt Fabric?

Felt is a textile material created by matting, condensing, and pressing fibers together. Unlike woven fabrics, which are made by interlacing threads at right angles, felt is constructed without a regular weave. This unique method of construction results in a dense, non-woven cloth that can be made from natural fibers such as wool or synthetic fibers like polyester or acrylic.

Components of Felt Fabric

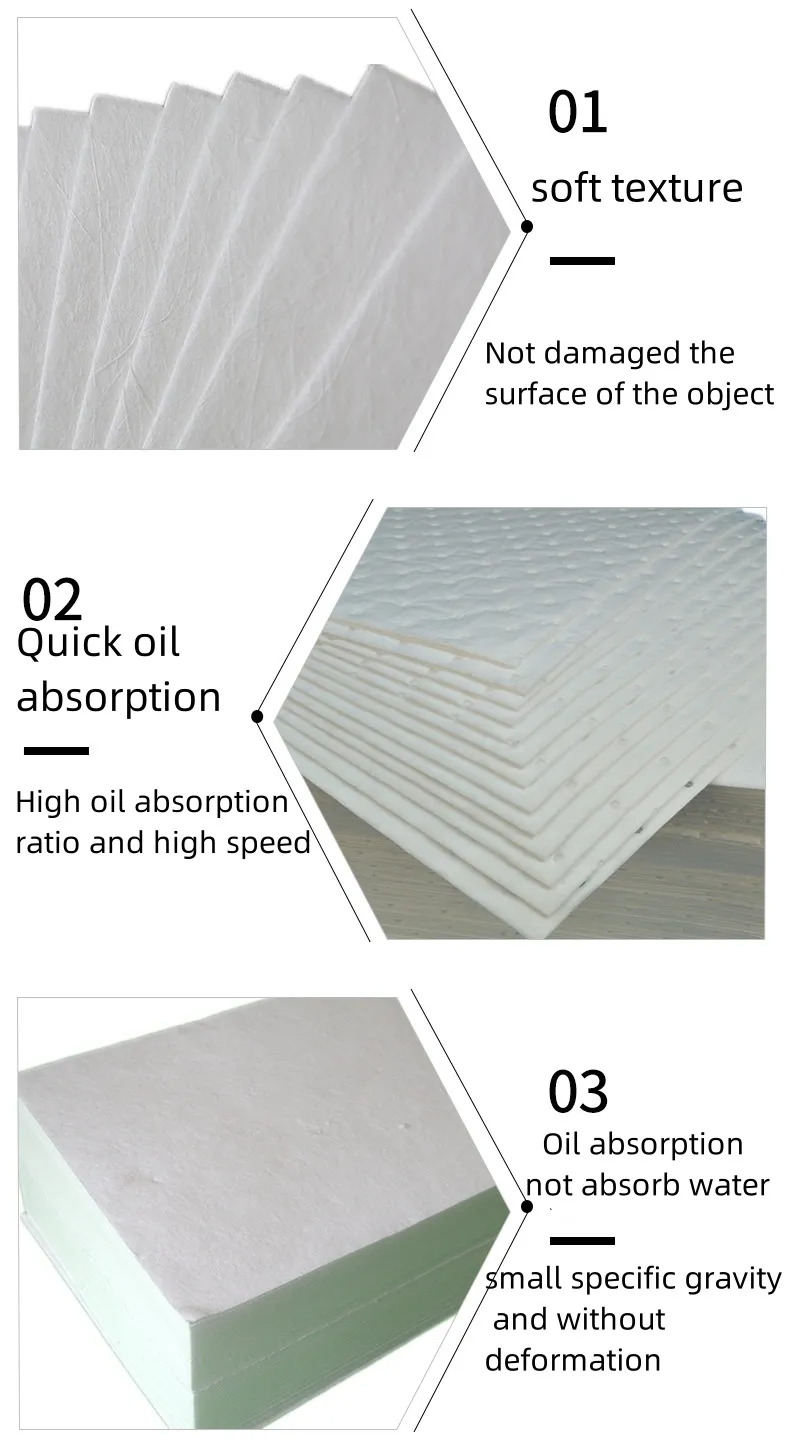

Felt can be categorized based on the type of fibers used. Wool felt, made from animal fibers, is one of the oldest forms of felt and is often valued for its softness, durability, and natural insulating properties. Synthetic felt, meanwhile, is created from man-made fibers and can offer benefits like water resistance and ease of cleaning. The choice of fiber significantly influences the properties of the final product, impacting factors like texture, flexibility, and durability.

Manufacturing Process of Felt Fabric

The process of making felt fabric involves several key stages

1. Preparation of Fibers The first step involves preparing the fibers, which may include cleaning, carding, and sometimes dyeing the materials. Carding aligns the fibers, making them easier to mat together.

2. Felting This is the heart of the felt-making process. The prepared fibers are layered and subjected to moisture, heat, and mechanical pressure. During this process, the scales on the fibers interlock, creating a dense, cohesive fabric. The felting can be done manually or using industrial machines, depending on the desired scale and uniformity of the final product.

3. Finishing After the felting process, the fabric may undergo several finishing processes, which can include trimming, shearing for texture, and additional treatments to enhance color or water resistance. Every step in the finishing process helps to determine the fabric's final appearance and texture.

4. Quality Control Ensuring the quality of felt fabric is paramount. Manufacturers conduct tests to check for durability, strength, and the overall quality of the material.

felt fabric construction

Advantages of Felt Fabric

Felt fabric boasts numerous advantages that contribute to its popularity across various sectors

- Durability Felt is known for its strength and resistance to wear, making it ideal for items that undergo frequent use, such as bags, rugs, and industrial applications.

- Insulation Thanks to its dense structure, felt provides excellent insulation, which is beneficial in both clothing and home products.

- Sound Absorption The unique construction of felt makes it a suitable choice for soundproofing applications, as it effectively dampens noise.

- Versatility Felt can be used in fashion, crafts, home décor, and industrial applications, showcasing its flexibility as a material.

- Biodegradability Natural felt, particularly wool felt, is biodegradable, making it an environmentally friendly choice compared to synthetic alternatives.

Applications of Felt Fabric

The applications of felt fabric are vast and varied. In the fashion industry, felt is often used for hats, handbags, and various accessories. In crafts, it serves as a popular material for DIY projects, offering ease of use and a wide range of colors. Industrially, felt is utilized in automotive interiors, sound insulation, and protective clothing. Furthermore, the softness and versatility of felt make it a beloved material in educational toys and felt boards for children.

Conclusion

In summary, felt fabric construction is a fascinating blend of tradition and innovation. With its unique properties and manufacturing processes, felt remains a vital fabric in various industries. Understanding the construction of felt helps recognize its potential and versatility in both functional and aesthetic applications. Whether in a high-end fashion piece or an industrial component, felt's enduring appeal is a testament to its remarkable construction and extensive utility.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024