industrial felt rolls

The Versatility of Industrial Felt Rolls An Essential Material for Diverse Applications

Industrial felt rolls are a remarkable material widely used in various industries due to their unique properties and versatile applications. Made from compressed fibers, felt rolls can be produced from different raw materials, including wool, synthetic fibers, and even recycled materials. This flexibility in composition makes industrial felt suitable for many uses, from insulation and padding to filtration and soundproofing.

One of the primary advantages of industrial felt is its excellent insulating properties. Felt rolls provide thermal insulation, helping to maintain desired temperatures in a variety of settings, whether in manufacturing facilities or installations requiring temperature control. This thermal resistance is particularly beneficial in the automotive and aerospace industries, where precise conditions are essential for optimal performance.

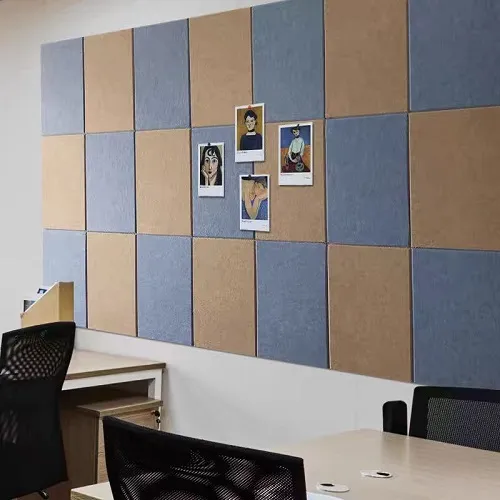

Moreover, industrial felt rolls are incredibly effective in soundproofing applications. The dense, fibrous structure of the felt absorbs sound waves, reducing noise pollution in environments such as factories, workshops, and even recording studios. The ability to control acoustics not only enhances comfort but also boosts productivity by creating a more conducive working environment.

In addition to insulation and soundproofing, industrial felt rolls are also used extensively for padding and cushioning. They are often employed in packaging and shipping applications to protect delicate items from damage during transit. The soft texture of the felt provides an ideal cushion, preventing scratches and impacts that can occur when products are moved or stored.

industrial felt rolls

Another notable application of industrial felt rolls is in filtration systems. The porous nature of felt allows it to trap particulates, making it an effective medium for filtering liquids and gases. Industries such as food and beverage, pharmaceuticals, and water treatment utilize felt rolls in their filtration systems to ensure the purity and safety of their products.

The manufacturing process of industrial felt rolls allows for customization, ensuring that businesses can meet specific requirements. Felt can be produced in various thicknesses, densities, and colors, making it easy to find a solution that fits particular operational needs. Moreover, advanced techniques such as needle punching and heat bonding can enhance the felt's performance characteristics, including durability and resistance to wear.

Sustainability is another vital aspect of industrial felt rolls. Many manufacturers are now producing felt from recycled materials, reducing waste and promoting an eco-friendly approach to production. This focus on sustainability not only helps the environment but also appeals to consumers who prioritize green practices in their purchasing decisions.

Overall, industrial felt rolls are an invaluable asset across a multitude of sectors. Their combination of insulation, sound absorption, cushioning, and filtration properties makes them an indispensable material in modern manufacturing and production processes. As industries continue to evolve, the demand for versatile, effective solutions such as industrial felt rolls will likely increase, underscoring their importance in meeting the diverse needs of various applications. Embracing innovation in felt technology will pave the way for even more exciting developments in the future, making it an essential component in the toolbox of countless industries.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024