Úno . 16, 2025 16:00

Back to list

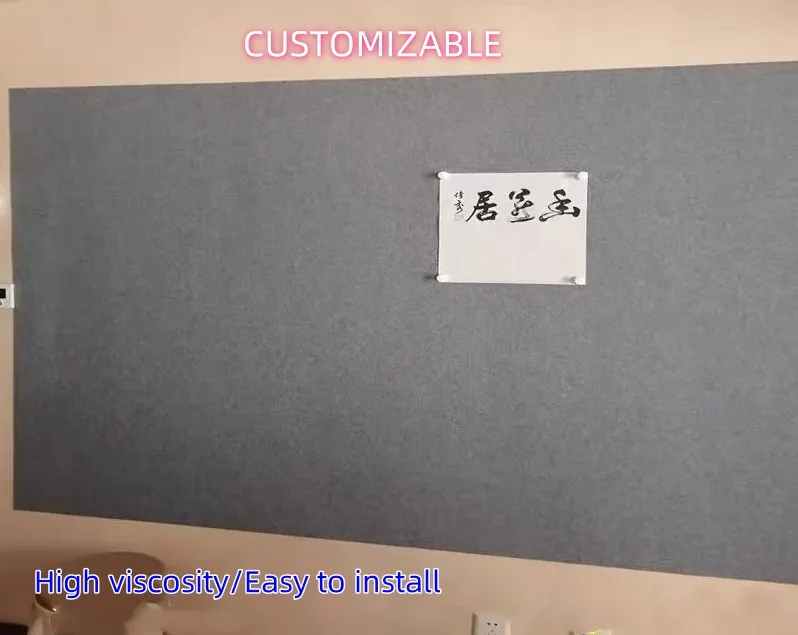

thick industrial felt

Thick industrial felt is an essential material used extensively across various sectors, providing unparalleled versatility and functionality. Its unique properties make it a preferred choice in industries such as manufacturing, construction, automotive, and soundproofing. Understanding the characteristics and benefits of thick industrial felt can offer insights into its widespread application and value addition to myriad projects.

Moreover, expertise in selecting the appropriate type of felt is crucial. Industry professionals emphasize the importance of assessing the specific requirements of a project. Wool-based felt might be chosen for applications needing excellent thermal insulation, whereas synthetic fibers might be preferred for superior moisture resistance or when a more economical option is required. Expertise in this domain is bolstered by years of field experience and comprehensive understanding of the properties of various felt compositions. Professionals proficient in these aspects demonstrate authoritative knowledge that aids in guiding clients toward optimal material choices that meet their project needs effectively. A growing trend in sustainable manufacturing underscores the importance of using eco-friendly materials. Wool felt, a natural product, checks this box as it is biodegradable and renewable. As sustainability takes center stage across industries, the trustworthiness of a supplier in providing eco-friendly thick industrial felt becomes all the more prominent. Companies that prioritize sustainable practices tend to establish stronger reputations, winning the trust of environmentally conscious clientele. Finally, the credibility of a supplier in delivering high-quality thick industrial felt cannot be overstated. Businesses seeking to incorporate felt in their operations would do well to partner with reputable manufacturers with proven track records of quality assurance. Trustworthiness in sourcing ensures not only the production of reliable goods but also contributes to overall brand integrity. In summary, thick industrial felt stands as a critical material in numerous industrial applications due to its unique properties of durability, thermal and acoustic insulation, chemical resistance, and shock absorption. Leveraging expertise in selecting the appropriate type of felt and ensuring sustainability in production underscores its importance across sectors. This multi-functional material promises to remain a staple solution as industries continue to evolve, ensuring optimized performance and enhanced sustainability.

Moreover, expertise in selecting the appropriate type of felt is crucial. Industry professionals emphasize the importance of assessing the specific requirements of a project. Wool-based felt might be chosen for applications needing excellent thermal insulation, whereas synthetic fibers might be preferred for superior moisture resistance or when a more economical option is required. Expertise in this domain is bolstered by years of field experience and comprehensive understanding of the properties of various felt compositions. Professionals proficient in these aspects demonstrate authoritative knowledge that aids in guiding clients toward optimal material choices that meet their project needs effectively. A growing trend in sustainable manufacturing underscores the importance of using eco-friendly materials. Wool felt, a natural product, checks this box as it is biodegradable and renewable. As sustainability takes center stage across industries, the trustworthiness of a supplier in providing eco-friendly thick industrial felt becomes all the more prominent. Companies that prioritize sustainable practices tend to establish stronger reputations, winning the trust of environmentally conscious clientele. Finally, the credibility of a supplier in delivering high-quality thick industrial felt cannot be overstated. Businesses seeking to incorporate felt in their operations would do well to partner with reputable manufacturers with proven track records of quality assurance. Trustworthiness in sourcing ensures not only the production of reliable goods but also contributes to overall brand integrity. In summary, thick industrial felt stands as a critical material in numerous industrial applications due to its unique properties of durability, thermal and acoustic insulation, chemical resistance, and shock absorption. Leveraging expertise in selecting the appropriate type of felt and ensuring sustainability in production underscores its importance across sectors. This multi-functional material promises to remain a staple solution as industries continue to evolve, ensuring optimized performance and enhanced sustainability.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024