felt process

The Felt Process A Journey from Fiber to Fabric

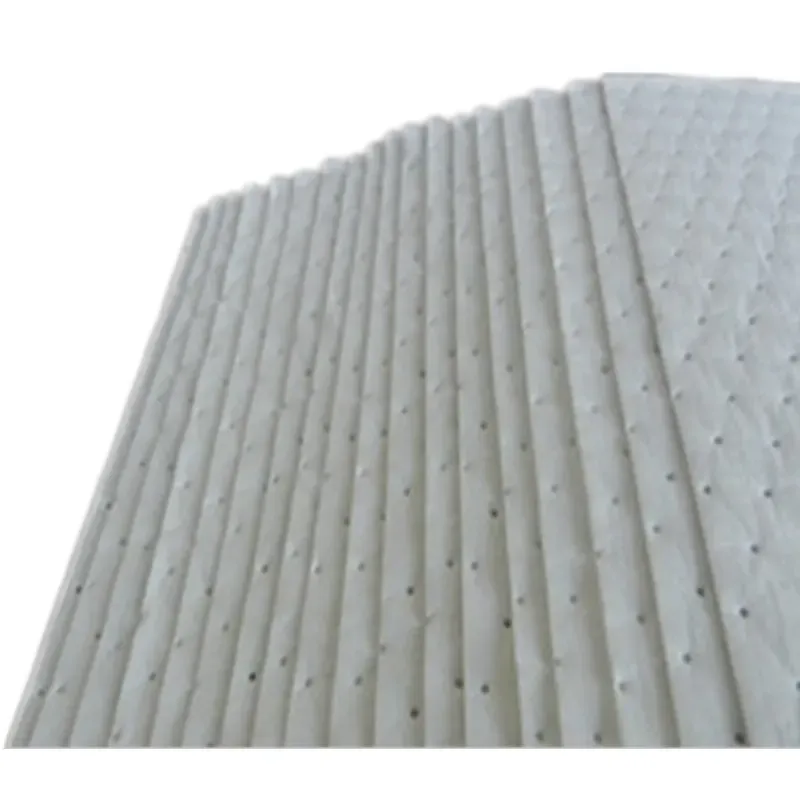

The felt process is a fascinating and ancient technique of textile production that transforms raw fibers into a dense, versatile fabric. Dating back thousands of years, felt has been utilized by various cultures for everything from clothing to shelter. This article explores the steps involved in the felt-making process, the types of fibers used, and the applications of this unique fabric.

Understanding Felt

Felt is a non-woven fabric created by matting, condensing, and pressing fibers together. Unlike woven or knitted fabrics, felt does not require a loom or knitting needles. Instead, it relies on the natural properties of fibers, particularly wool, which have scales that can interlock when subjected to heat, moisture, and agitation. This unique characteristic makes wool an ideal candidate for felting.

The Felt-Making Process

The felt-making process can be broken down into several key stages selecting fibers, preparing the material, laying out the fibers, felting, and finishing.

1. Selecting Fibers The most common fiber used in felt-making is wool, but other fibers such as alpaca, cashmere, and synthetic materials can also be used. The choice of fiber affects the texture, durability, and overall quality of the felt. Wool is preferred for its elasticity, warmth, and ability to retain shape.

2. Preparing the Material Before felting, the fibers must be cleaned and carded. Cleaning removes any dirt or grease, while carding untangles and aligns the fibers, making them easier to work with. This preparation is crucial for achieving an even felted fabric.

felt process

3. Laying Out the Fibers Once the fibers are prepared, they are laid out in thin layers, often in multiple directions. This cross-layering enhances the strength and stability of the final product. The amount of fiber used and how it is arranged can create different textures and thicknesses in the felt.

4. Felting The actual felting process involves applying heat, moisture, and agitation to the laid-out fibers. This is typically done by wetting the layers with soapy water and rubbing or rolling them to encourage the fibers to entangle. The friction and pressure cause the fiber scales to lock together, resulting in a dense, cohesive material. This process requires patience and care to achieve the desired thickness and firmness.

5. Finishing After the fibers have been felted, the material is rinsed and allowed to dry. Finishing techniques, such as trimming and dyeing, can enhance the aesthetic appeal of the felt. Various embellishments, such as stitching or beading, can also be added to create unique designs.

Applications of Felt

Felt is incredibly versatile, finding applications across various fields. In fashion, it is used to create hats, bags, and clothing, prized for its durability and insulating properties. In the interior design realm, felt is used for upholstery, wall coverings, and acoustic panels due to its sound-dampening qualities. Additionally, felt has gained popularity in the crafting community for making ornaments, toys, and decorative items.

Conclusion

The felt process is a testament to the ingenuity and resourcefulness of artisans throughout history. By understanding and mastering the steps involved in making felt, one can create beautiful and functional pieces that carry with them tradition and innovation. Whether used for practical purposes or artistic expression, felt continues to hold a significant place in the world of textiles, proving that some techniques stand the test of time.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024