felt manufacturer

Navigating the vast landscape of textile materials, one cannot overlook the significance of felt manufacturing. This unique fabric, renowned for its versatility and durability, plays an integral role in various applications—not only in fashion but also in industrial and artistic domains. As competition in the textile industry intensifies, felt manufacturers need to highlight their expertise, reliability, and innovative practices to stand out.

A felt manufacturer's journey begins with an intricate understanding of the fibers that make up this material. Wool, polyester, acrylic, and other blends provide different textures and functionalities. Manufacturers who emphasize their expertise in selecting high-quality raw materials instantly garner trust from discerning clients looking for durable and effective products. By showcasing this authority, they reassure clients that their felt products will meet desired standards and applications.

While expertise in material selection is fundamental, the manufacturing techniques employed are equally vital. Leading manufacturers leverage state-of-the-art facilities and advanced technology, such as needle punching and wet felting, to produce superior outcomes. Detailing these methods, and how they contribute to the final product durability and texture, not only emphasizes a manufacturer’s technical skill but also their commitment to delivering top-notch materials consistently.

Experience in the field further elevates a manufacturer’s profile. Years of hands-on engagement allow companies to refine their processes and explore innovative solutions tailored to specific industry needs. For instance, nonwoven felts used in automotive soundproofing require different specifications compared to those used in fashion accessories. Sharing case studies of successful projects or collaborations offers tangible proof of a manufacturer’s capacity to meet complex and varied demands.

felt manufacturer

Moreover, sustainability has become a defining aspect of trustworthiness in manufacturing. Today's consumers and businesses are increasingly inclined towards environmentally conscious choices. Thus, manufacturers who adopt eco-friendly practices, such as recycling water in the production process or using biodegradable fibers, demonstrate an investment in both quality and the planet’s future. Transparency in these processes can be divulged through certifications, detailed on the company’s website, adding to the manufacturer's credibility.

Furthermore, a seamless supply chain underscores the reliability of a felt manufacturer. Companies that maintain a robust logistics framework to ensure timely delivery and flexible order management set themselves apart. This reliability is vital, especially for businesses operating on tight deadlines or in need of customized solutions.

Finally, engaging with clients beyond the sale is crucial. Offering expert advice on the application and maintenance of felt materials adds value, ensuring customer satisfaction. A platform for feedback and continued dialogue serves as a testament to a company's commitment to client relationships, fostering trust and loyalty.

In conclusion, felt manufacturers positioned for success are those that intricately weave expertise, innovation, sustainability, and client-centric philosophies into their operations. By illuminating their distinct processes and values, these manufacturers not only carve out a niche in a competitive market but also establish a lasting reputation built on trust and authority.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

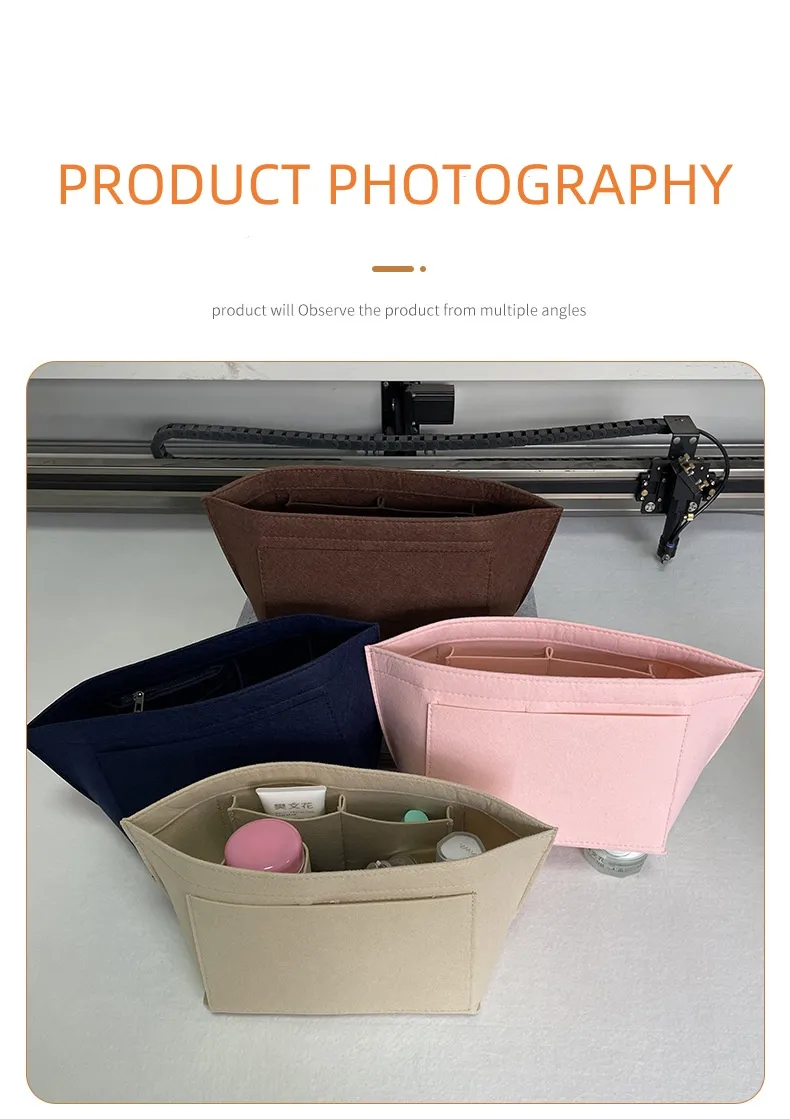

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024