Industrial Felt Solutions for Versatile Applications and Enhanced Durability in Various Industries

The Versatile World of Industrial Felt Products

Industrial felt products play a critical role in various industries, providing solutions that enhance efficiency, durability, and safety. This unique material, made from compressed fibers, offers numerous advantages, making it a preferred choice across a multitude of applications. To understand the significance of industrial felt, it’s essential to explore its properties, uses, and benefits.

Understanding Industrial Felt

Industrial felt is made from natural or synthetic fibers that are compressed and matted together. The manufacturing process involves needling or wet felting, resulting in a robust and dense material known for its insulating, sound-absorbing, and shock-absorbing qualities. Depending on the type of fibers used—such as wool, polyester, or acrylic—industrial felt can exhibit different characteristics, which can be tailored to meet specific industrial needs.

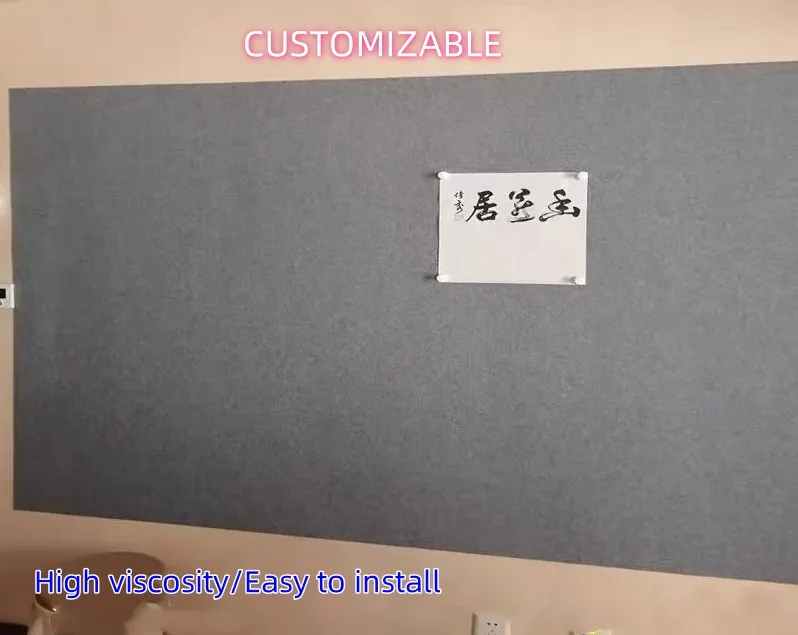

The versatility of industrial felt products is evident in their wide range of applications. They are employed in sectors like automotive, aerospace, textiles, construction, and manufacturing. The adaptability of felt means that it can be produced in various thicknesses, densities, and sizes, allowing it to meet the precise demands of different applications.

Applications of Industrial Felt

One of the most prevalent uses of industrial felt is in the automotive industry. Here, felt products serve multiple functions—from sound dampening to thermal insulation. Felt liners are often utilized within doors, dashboards, and engine compartments to minimize vibrations and reduce noise, enhancing the overall driving experience. The heat resistance of industrial felt further ensures that it remains effective even in high-temperature environments.

In the aerospace sector, industrial felt is renowned for its lightweight yet sturdy characteristics. It is frequently used in the production of insulation materials, pads, and gaskets that help in temperature regulation and noise reduction within aircraft cabins. The ability of felt to withstand extreme conditions while maintaining its integrity makes it indispensable in aerospace engineering.

industrial felt products

Another significant application can be found in the textile industry, where industrial felt is used as a backing material for carpets and textiles. Felt provides a stable foundation that improves the lifespan of carpets by offering protection against wear and tear. Additionally, felt's ability to absorb noise makes it an invaluable component in producing carpets designed for sound-sensitive environments.

Felt products also find extensive use in construction and manufacturing. They are commonly used as protective pads for heavy machinery, preventing scratches and damage to surfaces. In conveyor systems, felt strips are often applied to reduce friction between moving parts, improving operational efficiency and extending equipment life.

Benefits of Industrial Felt Products

The benefits of using industrial felt products are multifold. One of the primary advantages is their excellent insulation properties. Whether it’s thermal, sound, or vibration insulation, felt effectively reduces energy consumption and enhances comfort in various environments. This feature is particularly valuable in sectors where maintaining a specific temperature or noise level is essential.

Durability is another remarkable characteristic of industrial felt. Its ability to withstand high levels of wear and stress makes it a long-lasting solution, reducing the need for frequent replacements. This durability translates into cost savings for industries that rely on felt for numerous applications.

Furthermore, industrial felt is environmentally friendly, especially when made from natural fibers. Many manufacturers are now focusing on sustainable practices, creating felt products that are biodegradable and recyclable. This shift towards eco-friendly materials is not only beneficial for the environment but also aligns with the growing consumer demand for sustainable products.

Conclusion

In conclusion, industrial felt products are an essential component across various sectors, offering a versatile solution that meets the evolving demands of modern industries. Their unique properties, combined with a wide range of applications, highlight the significant role they play in enhancing efficiency, safety, and sustainability. As industries continue to innovate, the importance and utility of industrial felt products are likely to grow, paving the way for new applications and improved materials. Embracing industrial felt not only contributes to operational effectiveness but also supports a more sustainable future, reflecting the ongoing commitment to eco-friendly practices in manufacturing and production.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024