Мар . 04, 2025 01:12

Back to list

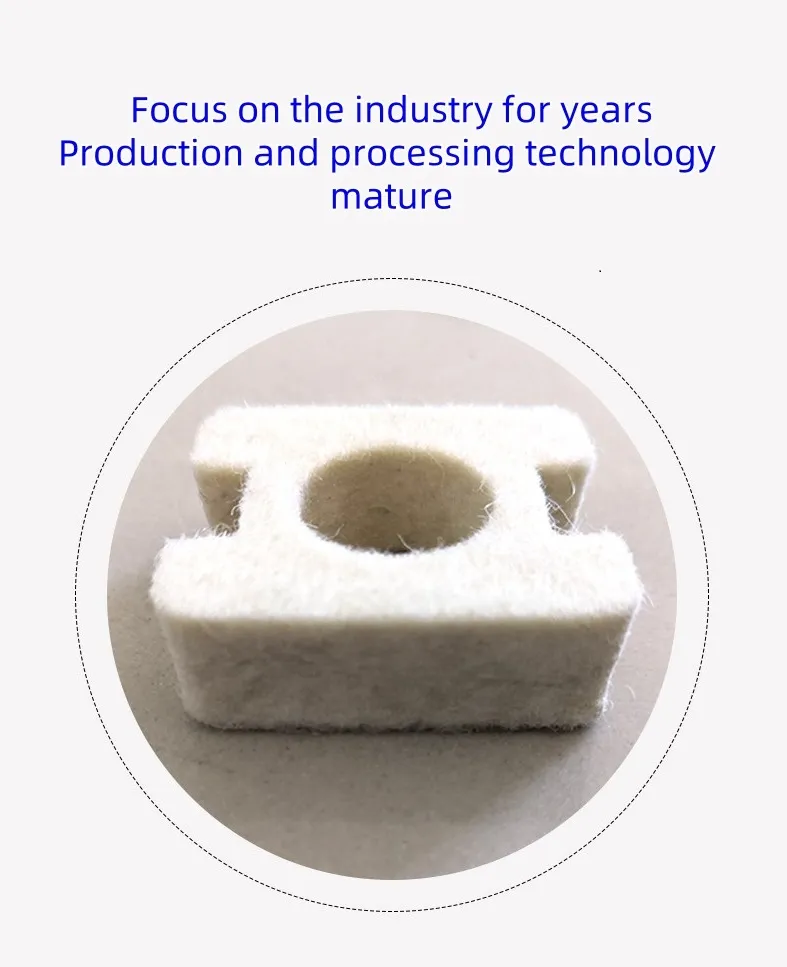

non woven needle felt

Non woven needle felt has carved a niche in various industries with its unique combination of strength, versatility, and cost-effectiveness. This material, created through a meticulous process involving entangling fibers by punching them together with barbed needles, is gaining acclaim for its wide application range—spanning from filtration systems to automotive components. In my extensive experience dealing with textile materials and filtration solutions, non woven needle felt stands out for several compelling reasons, and I aim to delve into its diverse applications, intrinsic properties, and why it's trusted across multiple domains.

Another critical application of non woven needle felt is in geotextiles, where it helps in soil stabilization and erosion control. Its robust nature allows it to withstand environmental stresses, including moisture and pressure fluctuations, making it an ideal solution for infrastructure projects ranging from roadways to landfill linings. Its ability to facilitate drainage while providing support is backed by extensive field studies and aligns with sustainable building practices. The credibility of non woven needle felt is further underscored by its environmental advantages. The manufacturing process, which can incorporate recycled materials, positions it as a sustainable choice amidst growing environmental concerns. In a world increasingly prioritizing sustainability, the capability of non woven needle felt to reduce waste and enhance resource efficiency cannot be overstated. Peer-reviewed research and environmental assessments vouch for its minimal ecological footprint, underpinning its role in progressive industry practices. Having examined non woven needle felt from both practical and technical viewpoints, it is evident that its integration into diverse applications is driven by a foundation of trust in its efficacy. Professionals and consumers alike endorse its qualities due to its demonstrated reliability across several fronts. As industries continue to evolve and seek out materials that align with technical requirements and sustainability, non woven needle felt remains a steadfast ally, offering a rare blend of tradition and innovation.

Another critical application of non woven needle felt is in geotextiles, where it helps in soil stabilization and erosion control. Its robust nature allows it to withstand environmental stresses, including moisture and pressure fluctuations, making it an ideal solution for infrastructure projects ranging from roadways to landfill linings. Its ability to facilitate drainage while providing support is backed by extensive field studies and aligns with sustainable building practices. The credibility of non woven needle felt is further underscored by its environmental advantages. The manufacturing process, which can incorporate recycled materials, positions it as a sustainable choice amidst growing environmental concerns. In a world increasingly prioritizing sustainability, the capability of non woven needle felt to reduce waste and enhance resource efficiency cannot be overstated. Peer-reviewed research and environmental assessments vouch for its minimal ecological footprint, underpinning its role in progressive industry practices. Having examined non woven needle felt from both practical and technical viewpoints, it is evident that its integration into diverse applications is driven by a foundation of trust in its efficacy. Professionals and consumers alike endorse its qualities due to its demonstrated reliability across several fronts. As industries continue to evolve and seek out materials that align with technical requirements and sustainability, non woven needle felt remains a steadfast ally, offering a rare blend of tradition and innovation.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024