ഫെബ്രു . 11, 2025 01:39

Back to list

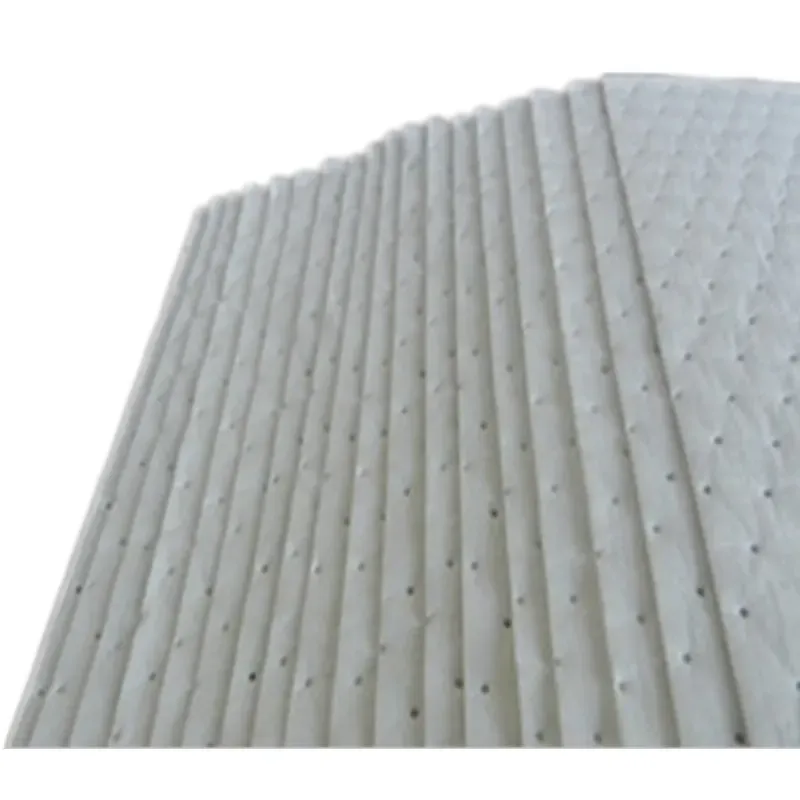

non woven felt

In the realm of industrial materials, non woven felt emerges as a textile marvel that efficiently combines innovative technology with practical applications. Known for its versatility, this medium has transformed from being just a basic fabric to an indispensable component across various industries including automotive, healthcare, construction, and fashion. With rapid advancements in manufacturing technologies, non woven felt has become a critical asset, prized for its exceptional properties such as durability, flexibility, and environmental sustainability.

The construction sector equally values non woven felt for its unique characteristics. Its application as a roofing underlay or as geotextiles in road construction demonstrates its durability under extreme conditions. Not only does it enhance structural integrity, but its thermal insulation capacities help in reducing energy consumption in buildings. The resilience of non woven felt to withstand mechanical stress and harsh weather conditions ensures longevity and reliability. For businesses looking to differentiate their offerings, non woven felt opens a realm of possibilities for customization. Incorporating innovative designs or incorporating functional enhancements such as flame retardancy or water repellency can add significant value. Fashion designers and artists have also begun exploring this material’s potential, creating artwork and fashion pieces that are both avant-garde and functional. In continuously exploring new horizons for non woven felt, companies and researchers collaborate to push the boundaries of what this material can achieve. The ongoing development in nanotechnology and smart textiles imbues non woven felt with capabilities like conductivity and responsive to stimuli, heralding a future where materials are not only passive enablers but active participants in technological ecosystems. In conclusion, non woven felt embodies the intersection of functionality and innovation, ensuring its position as a key material in the future of industrial applications. By meeting rigorous standards of Experience, Expertise, Authoritativeness, and Trustworthiness, stakeholders—from manufacturers to end-users—rely on and trust the capabilities of non woven felt for producing high-quality, sustainable, and efficient products. Pioneering efforts in research and development promise a continued trajectory of growth and innovation, further solidifying its indispensable role across diverse industry landscapes.

The construction sector equally values non woven felt for its unique characteristics. Its application as a roofing underlay or as geotextiles in road construction demonstrates its durability under extreme conditions. Not only does it enhance structural integrity, but its thermal insulation capacities help in reducing energy consumption in buildings. The resilience of non woven felt to withstand mechanical stress and harsh weather conditions ensures longevity and reliability. For businesses looking to differentiate their offerings, non woven felt opens a realm of possibilities for customization. Incorporating innovative designs or incorporating functional enhancements such as flame retardancy or water repellency can add significant value. Fashion designers and artists have also begun exploring this material’s potential, creating artwork and fashion pieces that are both avant-garde and functional. In continuously exploring new horizons for non woven felt, companies and researchers collaborate to push the boundaries of what this material can achieve. The ongoing development in nanotechnology and smart textiles imbues non woven felt with capabilities like conductivity and responsive to stimuli, heralding a future where materials are not only passive enablers but active participants in technological ecosystems. In conclusion, non woven felt embodies the intersection of functionality and innovation, ensuring its position as a key material in the future of industrial applications. By meeting rigorous standards of Experience, Expertise, Authoritativeness, and Trustworthiness, stakeholders—from manufacturers to end-users—rely on and trust the capabilities of non woven felt for producing high-quality, sustainable, and efficient products. Pioneering efforts in research and development promise a continued trajectory of growth and innovation, further solidifying its indispensable role across diverse industry landscapes.

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024