Exploring the Techniques and Materials Used in Felt Fabric Creation

Understanding Felt Fabric Construction

Felt fabric, a unique and versatile textile, has been utilized for centuries in various applications ranging from clothing to home décor. Its unique properties arise from a specific construction method that distinguishes it from other fabrics like woven or knitted textiles. Understanding how felt fabric is constructed not only highlights its unique characteristics but also reveals why it remains a popular choice in many fields today.

The Basics of Felt Fabric

Felt is a non-woven fabric, meaning it is not woven or knitted but rather matting and compressing fibers together. Traditionally, felt is made from natural fibers such as wool, but it can also be composed of synthetic materials like acrylic, polyester, or a combination thereof. The distinctive property of felt is its ability to be made without the need for a loom. This process can be traced back over 6,000 years, suggesting that felt crafting is one of humanity’s oldest textile techniques.

The Construction Process

The construction of felt fabric involves several key stages, primarily focusing on interfiber bonding. This bonding occurs through a combination of mechanical actions and heat, moisture, and pressure.

1. Fiber Selection The first step in felt construction is the selection of fibers. Wool is a popular choice due to its natural scales which interlock, enhancing the felting process. However, synthetic fibers can provide specific qualities such as increased durability or water resistance.

2. Carding Once the fibers are selected, they undergo a process called carding, where they are disentangled and aligned into a fluffy web. This web is essential as it prepares the fibers for the matting process.

3. Layering The carded fibers are then layered. The orientation of the fibers can vary; in some instances, fibers may be laid in a crisscross pattern to enhance durability in various directions.

4. Felting The actual felting process begins by applying moisture—often warm—along with agitation, which helps the fibers to bond together. This can be done manually, using a technique similar to kneading dough, or mechanically, with machines that apply necessary pressure and movement.

5. Finishing Once the desired thickness and density are achieved, the felt undergoes finishing processes. This stage may involve cutting, dying, or adding treatments that can enhance certain qualities such as water resistance or color-fastness.

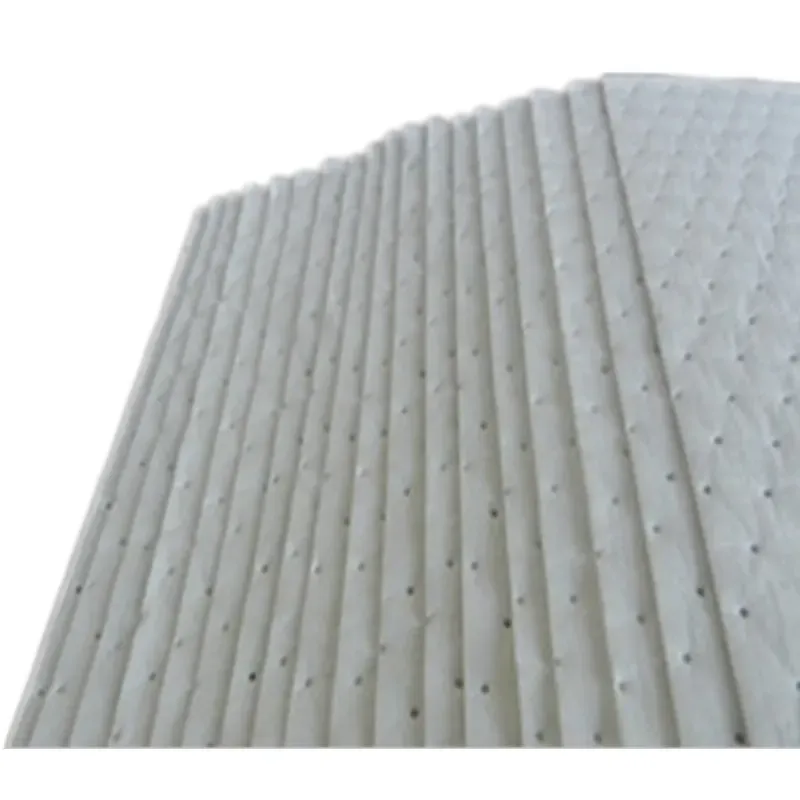

felt fabric construction

Properties of Felt Fabric

Felt fabric boasts several beneficial properties due to its construction method.

- Durability Felt is known for its long-lasting nature. The interlocked fibers create a robust structure that withstands wear and tear, making it suitable for various applications such as bags, shoes, and acoustic panels.

- Insulation Felt has excellent thermal insulation properties. This characteristic makes it an ideal choice for applications where temperature regulation is essential, including clothing and home furnishings.

- Sound Absorption Due to its dense structure, felt is effective in absorbing sound, which is why it is often used in soundproofing and acoustic panels.

- Eco-friendliness When made from natural fibers, felt is biodegradable and can be an environmentally friendly choice compared to many synthetic alternatives.

Applications of Felt Fabric

The versatility of felt fabric is evident in its wide range of applications. In fashion, felt is commonly used in hats, coats, and accessories due to its thermal properties and aesthetic appeal. In home décor, it serves as a popular choice for rugs, wall hangings, and craft projects.

Additionally, felt is widely used in industrial applications, including automotive interiors, insulation materials, and even in the production of educational toys due to its safety and durability.

Conclusion

Felt fabric construction is a fascinating blend of art and science, resulting in a material that is both functional and aesthetically pleasing. With its unique properties and wide range of applications, felt continues to hold a significant place in both traditional and contemporary textile practices. As the demand for sustainable and versatile materials grows, felt fabric is more relevant now than ever, promising to remain a beloved textile in various realms for years to come. Understanding its construction not only sheds light on its qualities but also invites us to appreciate the craftsmanship behind one of the oldest textiles known to humanity.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024