Feb . 03, 2025 02:35

Back to list

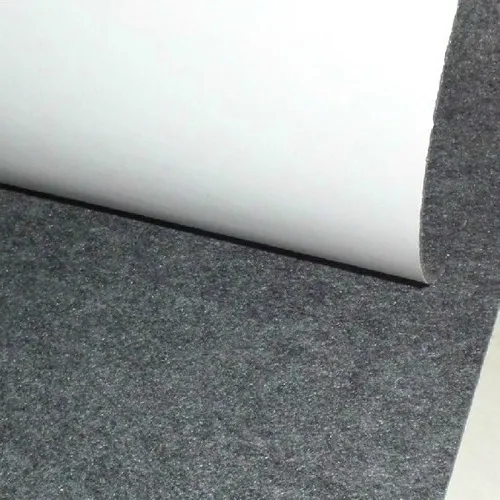

automotive felt

Automotive felt, a remarkable material making significant strides in the automotive industry, is truly a testament to the evolution of car manufacturing solutions. As vehicles become more sophisticated, the demand for materials that offer enhanced performance, reliability, and comfort continues to rise. Automotive felt perfectly addresses these demands, offering unparalleled benefits that extend from production to end-use.

Additionally, automotive felt's adaptability in terms of design and application speaks volumes about its expertise. It is readily customizable to fit intricate designs, an essential requirement given the complex configurations and dimensions of modern vehicles. This adaptability supports innovative automotive design and engineering, allowing for packaging solutions without compromising on aesthetic or functional quality. Automotive professionals trust felt not only for its tangible benefits but also for its implicit promise of safety. It is a non-toxic, hypoallergenic material ensuring that it is safe for both human contact and the environment. This attribute is particularly important in a confined car cabin environment, where materials must not emit harmful substances that could impact the occupants' health. Furthermore, OEMs (Original Equipment Manufacturers) recognize automotive felt’s authoritative role in enhancing thermal insulation. In extreme climates, temperature regulation within a vehicle is crucial for comfort as well as fuel efficiency in electric vehicles. Felt provides a barrier that keeps interiors cooler in summer and warmer in winter, thus optimizing the vehicle’s energy use. In conclusion, automotive felt embodies the pinnacle of material innovation within the car industry. Its palpable contribution to enhancing vehicle performance, passenger comfort, and environmental sustainability underscores its growing importance. As vehicles continue to integrate more advanced features, the role of reliable materials like automotive felt becomes increasingly vital. Companies opting for automotive felt are investing in a proven, trusted product that aligns with the future trajectory of automotive technology. Thus, automotive felt not only satisfies current industry needs but also sets a precedent for continued excellence and resilience in car manufacturing solutions.

Additionally, automotive felt's adaptability in terms of design and application speaks volumes about its expertise. It is readily customizable to fit intricate designs, an essential requirement given the complex configurations and dimensions of modern vehicles. This adaptability supports innovative automotive design and engineering, allowing for packaging solutions without compromising on aesthetic or functional quality. Automotive professionals trust felt not only for its tangible benefits but also for its implicit promise of safety. It is a non-toxic, hypoallergenic material ensuring that it is safe for both human contact and the environment. This attribute is particularly important in a confined car cabin environment, where materials must not emit harmful substances that could impact the occupants' health. Furthermore, OEMs (Original Equipment Manufacturers) recognize automotive felt’s authoritative role in enhancing thermal insulation. In extreme climates, temperature regulation within a vehicle is crucial for comfort as well as fuel efficiency in electric vehicles. Felt provides a barrier that keeps interiors cooler in summer and warmer in winter, thus optimizing the vehicle’s energy use. In conclusion, automotive felt embodies the pinnacle of material innovation within the car industry. Its palpable contribution to enhancing vehicle performance, passenger comfort, and environmental sustainability underscores its growing importance. As vehicles continue to integrate more advanced features, the role of reliable materials like automotive felt becomes increasingly vital. Companies opting for automotive felt are investing in a proven, trusted product that aligns with the future trajectory of automotive technology. Thus, automotive felt not only satisfies current industry needs but also sets a precedent for continued excellence and resilience in car manufacturing solutions.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024