Effective Use of Felt Buffing Wheels for Drills to Achieve a Polished Finish

The Advantages of Using a Felt Buffing Wheel for Drills

When it comes to polishing and finishing various materials, especially metals and plastics, the right tools can make all the difference. Among these tools, a felt buffing wheel is a standout choice for anyone looking to achieve a high-quality finish. When attached to a drill, a felt buffing wheel harnesses the power of rotary motion to deliver superior polishing capabilities. In this article, we'll explore the benefits and versatility of using felt buffing wheels in combination with drills, and how they can improve your crafting or industrial projects.

What is a Felt Buffing Wheel?

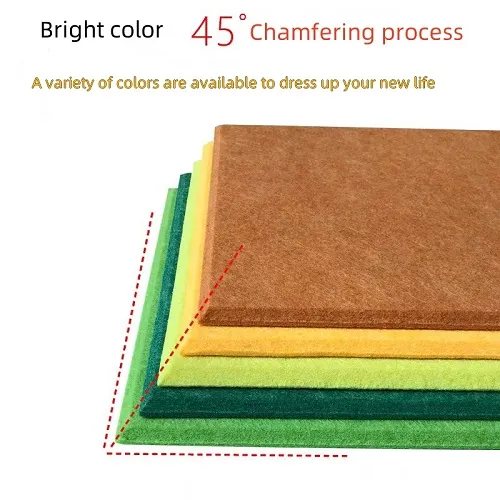

A felt buffing wheel is typically made from densely packed fibers of felt, offering a smooth and soft surface ideal for buffing. These wheels come in various sizes and thicknesses, making them suitable for different applications. They can be mounted easily on a standard drill, transforming your common tools into effective polishing machines. The gentle yet effective nature of felt makes it a preferred choice for delicate surfaces and complex shapes.

Key Advantages of Using Felt Buffing Wheels

1. Versatility Felt buffing wheels can be used on a wide range of materials, including metals, plastics, and wood. This versatility makes them invaluable for hobbyists, artisans, and professionals seeking to polish, buff, or finish various projects. Whether you're working on jewelry, automotive parts, or woodworking, a felt buffing wheel can be an essential tool in your arsenal.

2. High Polish Finish One of the most significant advantages of using felt buffing wheels is their ability to achieve a mirror-like finish. The fine fibers of the felt help to eliminate minor scratches and imperfections, resulting in a smooth and shiny surface. This makes them particularly useful for projects where aesthetics are paramount.

felt buffing wheel for drill

3. Ease of Use Attaching a felt buffing wheel to a drill is a straightforward process, making it easily accessible for both beginners and experienced users alike. The user-friendly design allows for quick changes between different wheels, saving valuable time on projects. With a simple setup, you can quickly switch from polishing to sanding as required.

4. Control Over Speed and Pressure Using a drill with a felt buffing wheel gives users control over the speed and pressure applied during the polishing process. This control is particularly beneficial when working with delicate materials that could be damaged under excessive pressure. You can adjust the drill's speed to ensure an optimal polishing effect without compromising the integrity of the workpiece.

5. Cost-Effective Solution Felt buffing wheels are generally affordable and can be reused multiple times, making them an economical choice for polishing projects. Compared to chemical polishes or more specialized polishing machines, felt wheels offer a budget-friendly alternative without sacrificing quality.

6. Minimal Heat Generation Unlike some other polishing methods, using felt buffing wheels on a drill minimizes the risk of generating excessive heat. This is crucial, especially when working with materials sensitive to temperature changes. Less heat means you can polish for longer periods without concern for damaging your workpiece.

Conclusion

In conclusion, a felt buffing wheel for a drill represents a practical and effective option for anyone looking to achieve a polished finish on various materials. Its versatility, ease of use, and ability to produce high-quality results make it a favored tool among DIY enthusiasts and professionals alike. By incorporating felt buffing wheels into your toolkit, you not only enhance your ability to finish intricate projects but also save time and money in the process. Whether you're a seasoned craftsman or just starting out, invest in felt buffing wheels to elevate your work to the next level.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024