Explore High-Quality Industrial Felt Options for Your Business Needs and Applications Today

Understanding the Importance of Purchasing Industrial Felt

Industrial felt is a versatile material widely used across various industries for a multitude of applications. Its unique properties make it an essential component in manufacturing, construction, automotive, and even artistic endeavors. In this article, we will explore the reasons behind the growing demand for industrial felt, its applications, and the factors to consider when purchasing it.

What is Industrial Felt?

Industrial felt is a non-woven fabric made from compressed fibers, typically wool, synthetic fibers, or a blend of both. The felting process transforms loose fibers into a solid material through heat, moisture, and pressure. This results in a dense, durable product that possesses excellent insulation, sound absorption, and cushioning properties. With its robustness and adaptability, industrial felt can be tailored for specific applications, making it a popular choice among manufacturers.

Wide Range of Applications

One of the primary reasons to buy industrial felt is its diverse range of applications

1. Soundproofing Industrial felt is an excellent sound absorber, making it ideal for use in music studios, theaters, and manufacturing facilities where noise reduction is essential.

2. Insulation Due to its density, industrial felt provides thermal insulation, which is crucial in construction and HVAC systems. It helps in maintaining temperature and energy efficiency.

3. Packaging The cushioning properties of felt make it an excellent choice for protective packaging. It helps safeguard delicate items and machinery during transport and storage.

4. Automotive Industry Industrial felt is utilized in the automotive sector for sound dampening, insulation, and to provide a finished look to interior components. It is used in headliners, door panels, and carpeting.

buy industrial felt

5. Crafting and Artwork Artisans use industrial felt in crafting and design due to its easy cut and shape properties. It can be dyed and shaped, allowing for creative applications in both art and textile industries.

Factors to Consider When Purchasing Industrial Felt

When considering the purchase of industrial felt, several factors are essential to ensure you get the most suitable product for your needs

1. Material Type Choose between natural fibers (like wool) and synthetic options (such as polyester or acrylic). Each has its own set of properties, such as strength, absorbency, and durability. Natural fibers offer environmental benefits, while synthetics may provide better resistance to moisture and chemicals.

2. Thickness and Density Depending on your application, the thickness and density of the felt will matter. Thicker felt is better for acoustic insulators, while thinner, more flexible varieties might be suitable for crafting or packing.

3. Temperature and Moisture Resistance If the felt will be exposed to extreme temperatures or humidity, it is crucial to select a type that can withstand those conditions. Research the specifications to ensure longevity in your application.

4. Sourcing and Quality Reputable suppliers will provide detailed specifications and quality guarantees. Look for manufacturers that offer samples for testing to ensure the felt meets your requirements for performance and quality.

5. Cost and Quantity Finally, consider your budget and the quantity needed. Buying in bulk can often lead to substantial savings, while negotiating with suppliers can also help reduce costs.

Conclusion

Investing in industrial felt can significantly benefit your operations, whether in manufacturing, construction, or creative projects. By understanding its properties, applications, and factors to consider for purchase, you can make informed decisions that will lead to successful outcomes. As industries continue to evolve, the demand for high-quality industrial felt is likely to rise, making it a valuable addition to your material inventory.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

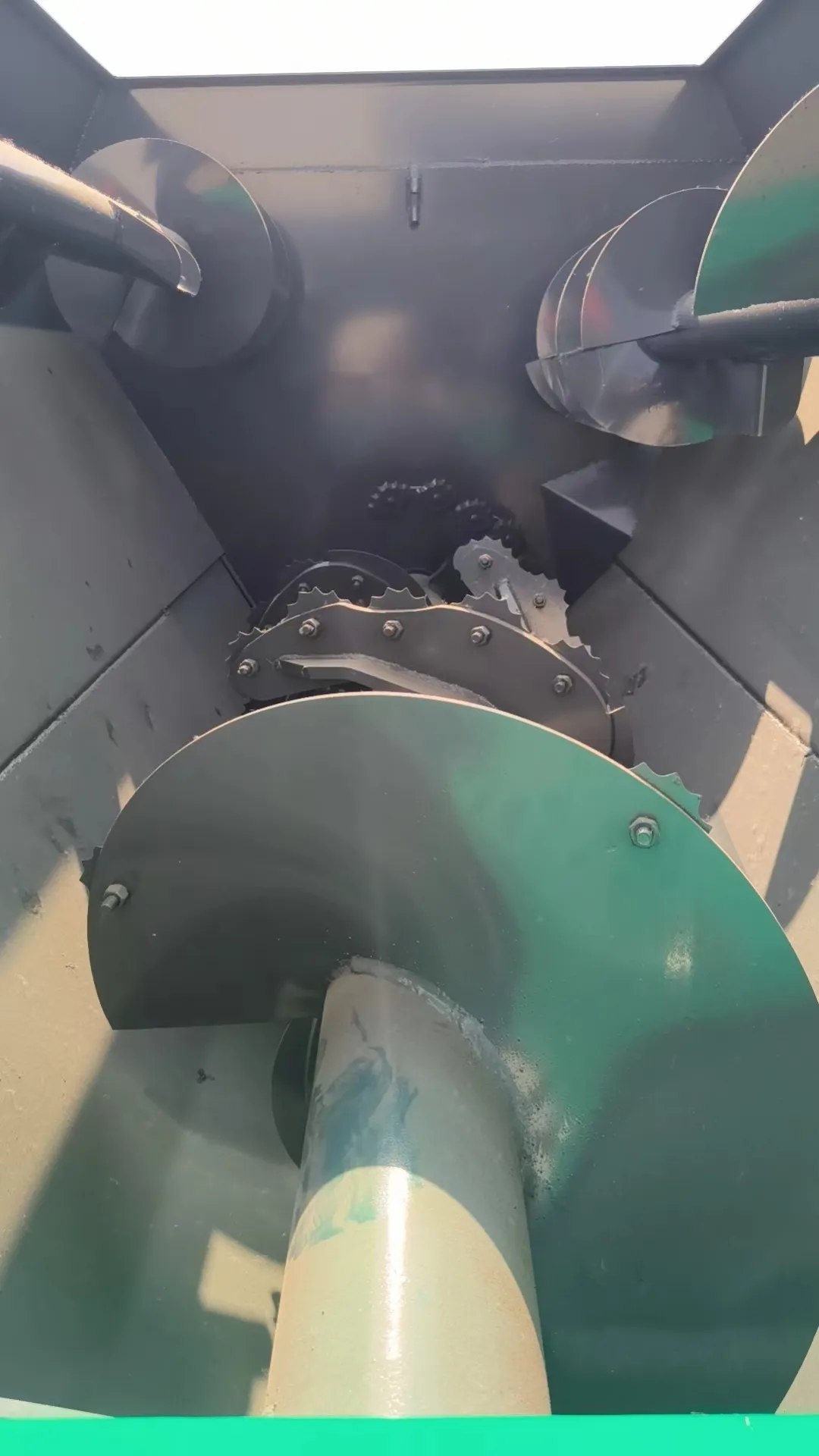

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024