Exploring the Benefits and Uses of Felt Buffing Wheels for Polishing and Finishing Tasks

The Versatility of Felt Buffing Wheels in Surface Finishing

Felt buffing wheels are essential tools in various industries for achieving a smooth, polished finish on a multitude of surfaces. Their versatility, durability, and ability to produce a high-gloss finish make them a favorite among professionals and hobbyists alike. In this article, we will explore the composition, applications, advantages, and maintenance of felt buffing wheels.

Composition and Structure

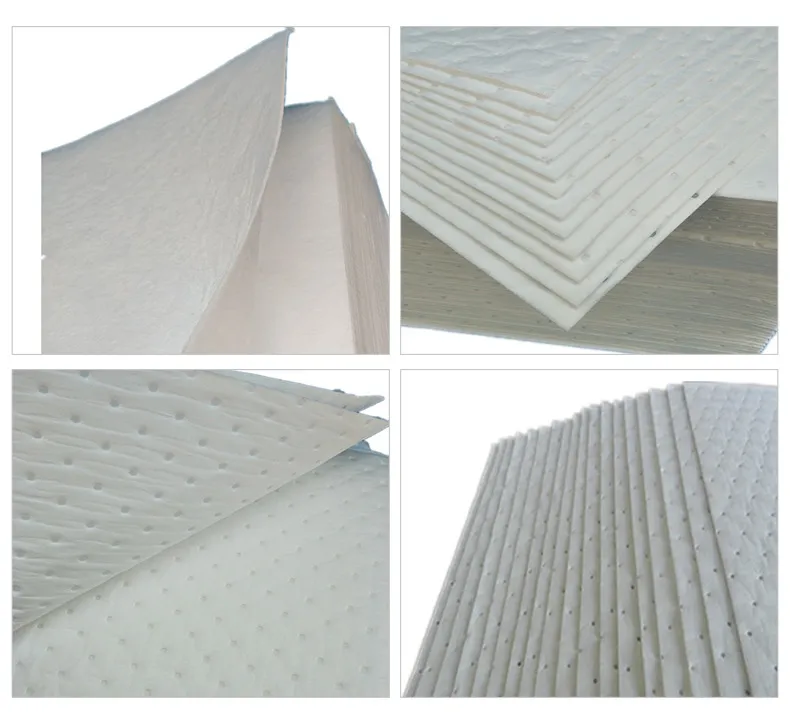

Felt buffing wheels are typically made from pressed wool fibers, which have been compacted into dense discs. This structure allows for both flexibility and durability. The fibers can be treated with different compounds, enabling the wheels to perform a variety of polishing and buffing tasks. The density and thickness of the wheel can vary, influencing its suitability for different applications. Some wheels are designed for fine polishing, while others may be more aggressive, suitable for initial buffing stages.

Applications in Various Industries

Felt buffing wheels are commonly used in metalworking, woodworking, jewelry making, and automotive refinishing. In metalworking, they are invaluable for polishing stainless steel, brass, copper, and aluminum, bringing out a brilliant shine and minimizing surface imperfections. Woodworkers use them to achieve a smooth finish on furniture, enhancing both aesthetics and durability. Jewelry makers rely on these wheels to apply polishing compounds to metals and gemstones, ensuring that their pieces glimmer and stand out.

In the automotive industry, felt buffing wheels are often employed to polish painted surfaces, ensuring a showroom-quality finish. They help to remove swirl marks and scratches, making vehicles look brand new. Furthermore, felt wheels can be used in the application of waxes and sealants, ensuring optimum protection against environmental elements.

Advantages of Felt Buffing Wheels

felt buffing wheel

There are several advantages to using felt buffing wheels. Firstly, they are adaptable to different polishing compounds, allowing users to choose the right treatment for their specific needs. Additionally, the soft yet durable nature of the felt means they can conform to various shapes and surfaces, making them ideal for both flat and contoured items.

Another significant benefit is their efficiency in reducing time and effort. When used correctly, felt buffing wheels can produce an exceptional finish in a fraction of the time compared to manual polishing methods. They minimize the risk of heat build-up, which can damage sensitive materials, thus ensuring a consistent and high-quality result.

Maintenance and Usage Tips

To maximize the lifespan and effectiveness of felt buffing wheels, proper maintenance is essential. After each use, it’s important to clean the wheel to remove any debris or polishing compound residue. This can be done with a pointed tool or a stiff brush. Regular conditioning of the wheel with suitable compounds will also enhance its performance.

When using felt buffing wheels, it's crucial to match the wheel to the task at hand. The speed of the machine and the pressure applied during usage can significantly affect the outcome. A slower speed, combined with light pressure, is often more effective for achieving a high-gloss finish without damaging the material.

Conclusion

Felt buffing wheels are indispensable tools that provide an efficient and effective means of achieving a polished surface in various industries. Their versatility in application, ease of use, and ability to produce high-quality results make them a go-to choice for professionals seeking flawless finishes. By understanding their composition, applications, and maintenance, users can proficiently utilize felt buffing wheels to enhance their projects—whether they be in metalwork, woodworking, jewelry making, or automotive refinishing.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024