Exploring the Versatility and Applications of Non-Woven Felt in Various Industries and Crafts

The Versatility of Non-Woven Felt An In-Depth Look

Non-woven felt, a fabric-like material created by bonding fibers together through various methods, has gained significant attention across multiple industries due to its unique characteristics and versatility. Unlike traditional woven fabrics, non-woven felt offers a range of advantages, making it a popular choice for applications in crafting, automotive, construction, and even medical fields.

What is Non-Woven Felt?

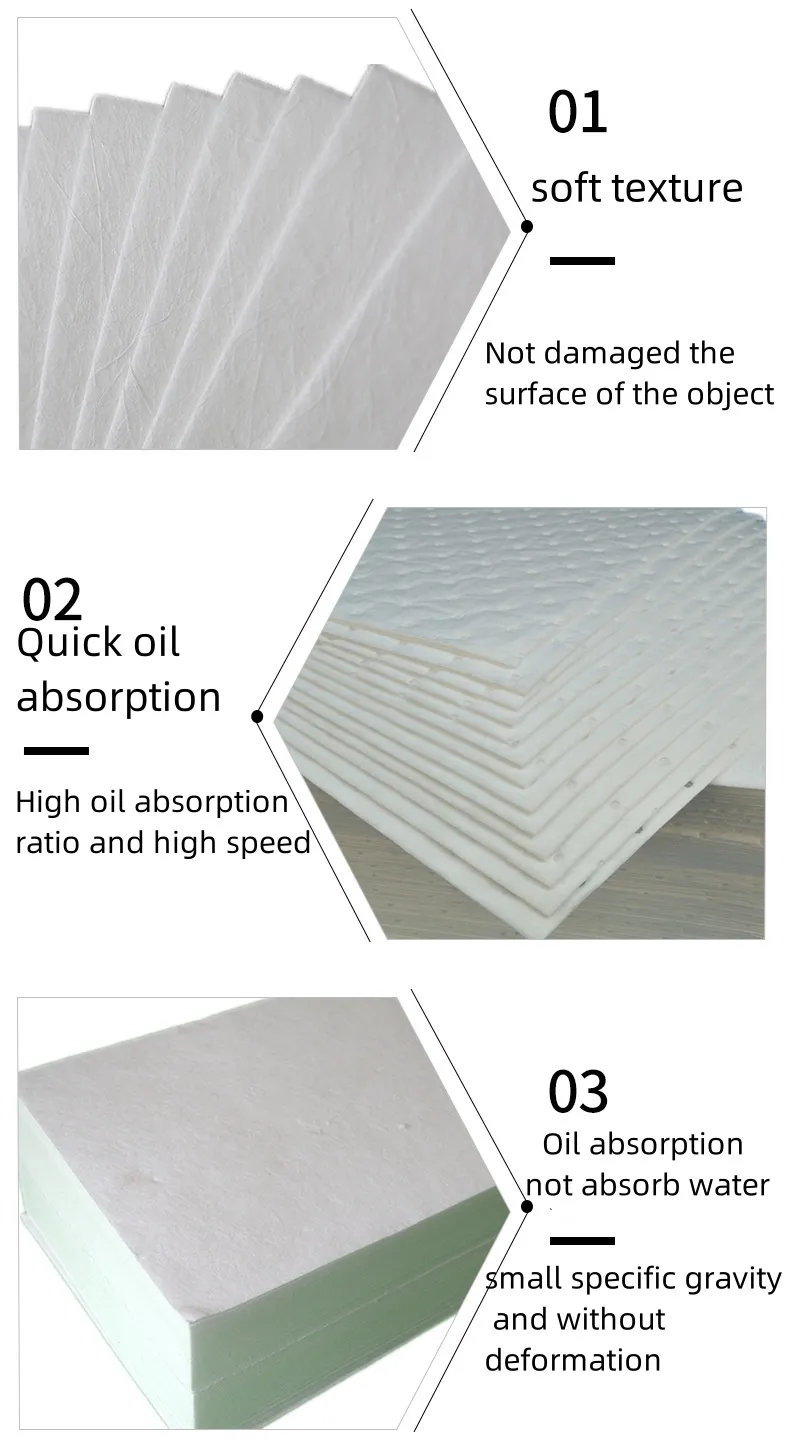

At its core, non-woven felt is made from fibers that are entangled, pressed, or heated to create a solid, cohesive material without the need for weaving or knitting. This process can utilize natural fibers, such as wool or cotton, as well as synthetic fibers like polyester and polypropylene. The result is a dense, durable substance that can vary in thickness, texture, and color, catering to various customer needs and aesthetic preferences.

Properties and Benefits

One of the most significant advantages of non-woven felt is its strength and durability. The fibers are densely packed, providing a robust material that can withstand wear and tear. Additionally, non-woven felt is often water-resistant and can be treated for increased resistance to mold and mildew, making it suitable for both indoor and outdoor applications.

Another critical property is its sound-absorbing capabilities. The unique structure of non-woven felt allows it to effectively dampen sound, making it an ideal choice for soundproofing applications in commercial spaces, studios, and even residential homes. This attribute has become increasingly important as more people invest in creating tranquil environments, whether for work or relaxation.

non woven felt

Furthermore, non-woven felt is naturally insulating. It can help maintain temperatures, making it valuable for thermal insulation in various settings, from automotive interiors to building materials. This characteristic not only enhances energy efficiency but also adds to the comfort of any space.

Applications Across Industries

The applications of non-woven felt are both vast and varied. In the crafting world, non-woven felt is a favorite among enthusiasts for its ease of use. It doesn’t fray like traditional fabric, allowing for clean cuts and versatile applications in projects ranging from toys and ornaments to home decor and fashion.

In the automotive industry, non-woven felt plays a critical role in the production of interior components. It is often used in lining for panels, trunks, and dashboards, not only for aesthetic appeal but also for its sound-dampening properties. Moreover, the material is lightweight, contributing to overall vehicle efficiency.

The construction industry also employs non-woven felt, especially in roofing and insulation. It serves as a reliable barrier against moisture, ensuring the longevity of building structures. Its durability and resistance to weather elements further bolster its position as a preferred material in construction applications.

Conclusion

Non-woven felt stands out as a functional and adaptable material that meets the demands of various industries. Its unique properties—ranging from durability and sound absorption to insulation—make it a go-to choice for professionals and hobbyists alike. As technology advances and innovation continues, the potential uses of non-woven felt are likely to expand even further, solidifying its position as a vital material in a range of applications. Whether you’re a crafter, industry professional, or simply someone interested in sustainable materials, non-woven felt offers endless possibilities.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024