Exploring the Versatility of Non-Woven Needle Felt in Various Industrial Applications and Crafts

Understanding Non-Woven Needle Felt A Versatile Material for Various Applications

Non-woven needle felt has gained popularity in various industries due to its unique properties and wide-ranging applications. Unlike traditional woven fabrics, needle felt is created through a process that intertwines fibers together using barbed needles. This innovative method results in a dense, durable, and versatile material that is used in numerous products and industries, including automotive, construction, filtration, and textiles.

Production Process

The production of non-woven needle felt begins with selecting appropriate fibers, which can be synthetic, natural, or a blend of both. Common materials used include polyester, polypropylene, and wool. After selecting the fibers, they are carded to align them in a random manner, creating a homogeneous web of fibers. This web is then subjected to needle punching, where barbed needles penetrate the fiber mat, entangling the fibers together and forming a cohesive structure. The result is a fabric-like material that exhibits excellent strength and durability while retaining flexibility.

Advantages of Non-Woven Needle Felt

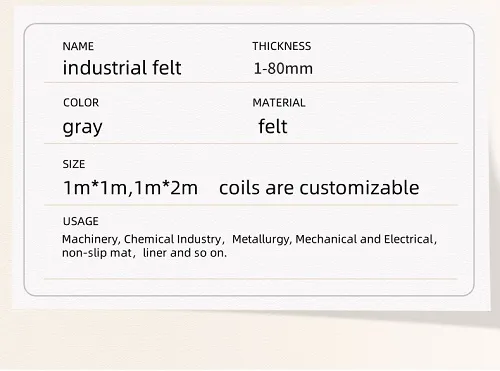

One of the primary advantages of non-woven needle felt is its ability to be customized to meet specific needs. Manufacturers can adjust the density, thickness, and fiber composition, making it an ideal choice for a variety of applications. Additionally, needle felt is resistant to moisture, chemicals, and UV radiation, making it suitable for outdoor use and environments where durability is crucial.

Another significant benefit of using non-woven needle felt is its sound-absorbing properties. This characteristic makes it popular for use in soundproofing applications within buildings and vehicles, effectively reducing noise pollution and improving overall comfort.

non woven needle felt

Furthermore, non-woven needle felt is known for its sustainability. Many manufacturers are now producing needle felts from recycled materials, which aligns with the growing demand for environmentally friendly products. This not only helps reduce waste but also minimizes the carbon footprint associated with the production of new materials.

Applications

The versatility of non-woven needle felt allows it to be utilized in a myriad of applications. In the automotive industry, it is used for interior components, sound insulation, and thermal insulation. The construction industry also benefits from its use in roofing, insulation, and as a geotextile material for erosion control.

In the realm of filtration, non-woven needle felt is often employed in air and liquid filtration systems. Its structure allows for efficient trapping of particles while maintaining a flow rate. This effectiveness makes it essential for applications ranging from industrial processes to HVAC systems in commercial buildings.

Additionally, non-woven needle felt is increasingly used in the textile industry for various purposes, including clothing, accessories, and crafting materials. Its unique texture and ability to hold dyes well make it an attractive choice for designers and manufacturers.

Conclusion

Non-woven needle felt is a remarkable material that offers a range of benefits and applications. Its robust nature, coupled with its customizable features, makes it a superior choice for many industries. As sustainability concerns continue to grow, the production of eco-friendly needle felt from recycled materials is set to further enhance its appeal. Whether in automotive, construction, filtration, or textiles, non-woven needle felt stands out as a practical and innovative solution for modern manufacturing and design challenges. With its numerous advantages and versatility, it is clear that non-woven needle felt will continue to play a significant role in various sectors for years to come.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024