Felt Polishing Wheels for Drills Enhancing Surface Finish and Shine

The Versatility and Importance of Felt Polishing Wheels for Drills

Felt polishing wheels have become a vital tool for many craftsmen, hobbyists, and industrial professionals. These tools are especially effective when used with drills, providing precision and efficiency in polishing various materials. In this article, we will explore the advantages of using felt polishing wheels, their applications, and tips on how to utilize them effectively.

What are Felt Polishing Wheels?

Felt polishing wheels are circular disks made from compressed felt material. They come in various sizes and thicknesses, designed to fit onto standard drill chucks or mandrels. The soft, fibrous texture of felt makes it an ideal medium for polishing, buffing, and finishing a variety of surfaces. When attached to a drill, these wheels rotate at high speeds, allowing for effective polishing action with minimal effort.

Advantages of Using Felt Polishing Wheels

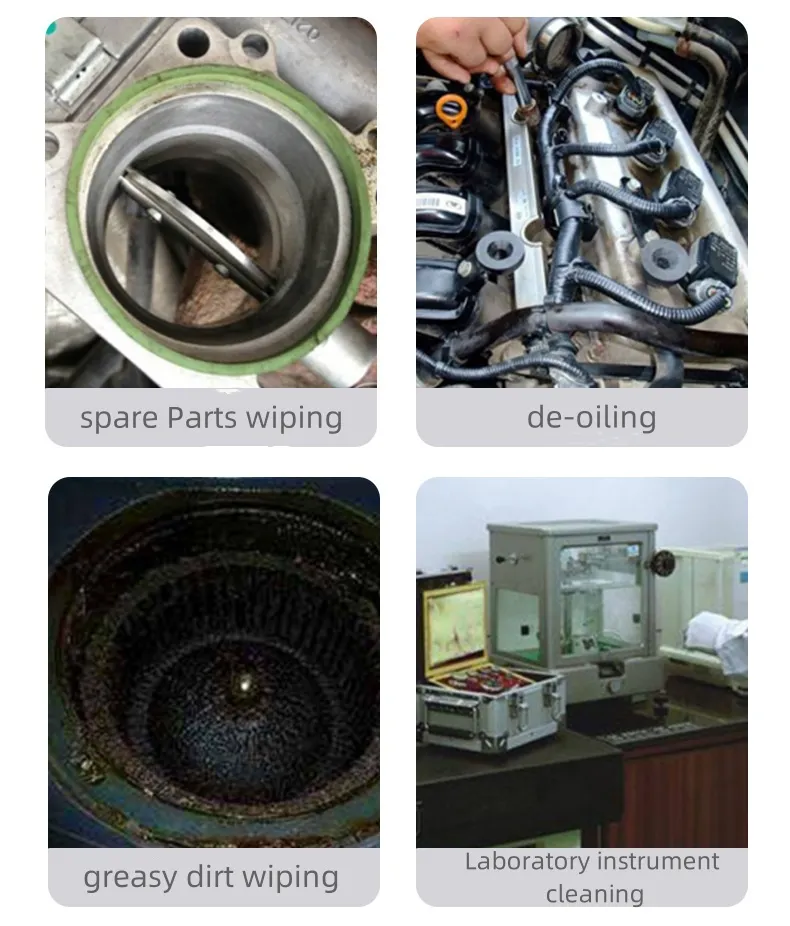

One of the primary advantages of felt polishing wheels is their versatility. They can be used on a range of materials, including metals, plastics, glass, and ceramics. Felt polishing wheels can achieve a high-gloss finish on surfaces, making them ideal for projects requiring a polished look. Additionally, these wheels are available in different densities and grades, allowing users to choose the right wheel for their specific polishing needs.

Another significant benefit is the efficiency and speed they bring to the polishing process. Traditional hand-polishing methods can be time-consuming, requiring considerable physical effort and time. In contrast, when used with a drill, felt polishing wheels can cover larger areas in a fraction of the time, making them suitable for both large-scale manufacturing and smaller home projects.

Moreover, felt polishing wheels are relatively easy to use. A basic understanding of how to attach the wheel to the drill and apply the right amount of pressure is often all that is required to achieve great results. This accessibility makes them appealing to users ranging from professionals to beginners.

Applications of Felt Polishing Wheels

felt polishing wheel for drill

Felt polishing wheels are utilized across various industries and crafts. In jewelry making, for instance, these wheels are perfect for buffing metal components to achieve a brilliant shine. Similarly, in woodworking, they can be used to polish wooden surfaces and bring out the natural grain.

In the automotive industry, felt polishing wheels are employed to polish chrome, aluminum, and even painted surfaces. They can help remove oxidation, scratches, and other imperfections, enhancing the overall aesthetic of vehicles. Additionally, hobbyists often use these wheels for model building and craftsmanship, allowing for detail work on small pieces with precision.

How to Use Felt Polishing Wheels Effectively

To maximize the effectiveness of felt polishing wheels, it is essential to follow some best practices. First, select the right wheel for your project. Different felt density levels cater to different polishing tasks; softer wheels are suited for delicate surfaces, while firmer wheels are better for heavy materials.

When using the wheel, ensure that it is properly attached to the drill to avoid accidents. Start at a low speed to familiarize yourself with the handling and gradually increase the RPM as needed. A consistent, moderate pressure is crucial—too much pressure can wear out the wheel quickly or damage the surface being polished.

It is also advisable to apply an appropriate polishing compound to the felt wheel for optimal results. This compound will enhance the wheel's effectiveness, enabling it to remove tarnish, oxidation, and light scratches while providing a polished finish.

Finally, always ensure proper safety measures are in place while working with polishing wheels. Protective eyewear is essential to safeguard against debris, and a dust mask can help avoid inhaling any particles from the material being polished.

Conclusion

Felt polishing wheels for drills present an excellent solution for those seeking efficiency and high-quality finishes in their projects. Their versatility across various materials and ease of use make them an indispensable tool in both professional settings and hobbyist workshops. By employing best practices and utilizing the appropriate wheels, users can achieve striking results, enhancing their craftsmanship and product outcomes. Whether in the field of jewelry making, woodworking, or automotive detailing, felt polishing wheels are sure to provide reliable performance and remarkable results.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024