Jan . 10, 2025 09:33

Back to list

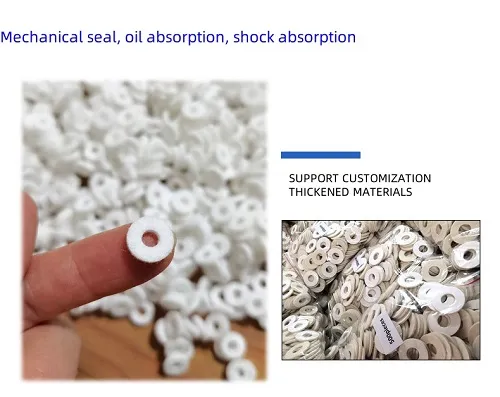

Felt sealing ring

Thick industrial felt is an unsung hero in the world of materials, blending unique characteristics that cater to various industrial applications requiring superior resilience and adaptability. Crafted meticulously from natural or synthetic fibers, this material's distinct properties make it indispensable across different sectors, including automotive, construction, and manufacturing.

Trust in thick industrial felt extends from its historical use and the continuous innovations enhancing its functionality. With its fibers derived from wool and other renewable sources, this material aligns with sustainable practices, becoming a preferred choice for industries aiming to reduce their ecological footprint. Its recyclability and minimal environmental impact appeal to environmentally conscious decision-makers, fostering a reputation for both reliability and responsibility. The dedication to refining thick industrial felt’s production underscores its authority in industrial applications. Manufacturers leverage sophisticated techniques to enhance the felt's properties, ensuring it meets rigorous industry standards. This commitment to quality fortifies the credibility of felt among engineers and project managers worldwide, who value reliable materials that enhance performance and efficiency. Ultimately, the exceptional performance of thick industrial felt in diverse applications speaks to its value. Experts consistently rank it among top materials for protective and insulative purposes, reinforcing its authoritative status across industries. Building on its reputation for reliability and adaptability, thick industrial felt continues to establish itself as the material of choice for those seeking durable and efficient solutions in a variety of demanding applications.

Trust in thick industrial felt extends from its historical use and the continuous innovations enhancing its functionality. With its fibers derived from wool and other renewable sources, this material aligns with sustainable practices, becoming a preferred choice for industries aiming to reduce their ecological footprint. Its recyclability and minimal environmental impact appeal to environmentally conscious decision-makers, fostering a reputation for both reliability and responsibility. The dedication to refining thick industrial felt’s production underscores its authority in industrial applications. Manufacturers leverage sophisticated techniques to enhance the felt's properties, ensuring it meets rigorous industry standards. This commitment to quality fortifies the credibility of felt among engineers and project managers worldwide, who value reliable materials that enhance performance and efficiency. Ultimately, the exceptional performance of thick industrial felt in diverse applications speaks to its value. Experts consistently rank it among top materials for protective and insulative purposes, reinforcing its authoritative status across industries. Building on its reputation for reliability and adaptability, thick industrial felt continues to establish itself as the material of choice for those seeking durable and efficient solutions in a variety of demanding applications.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

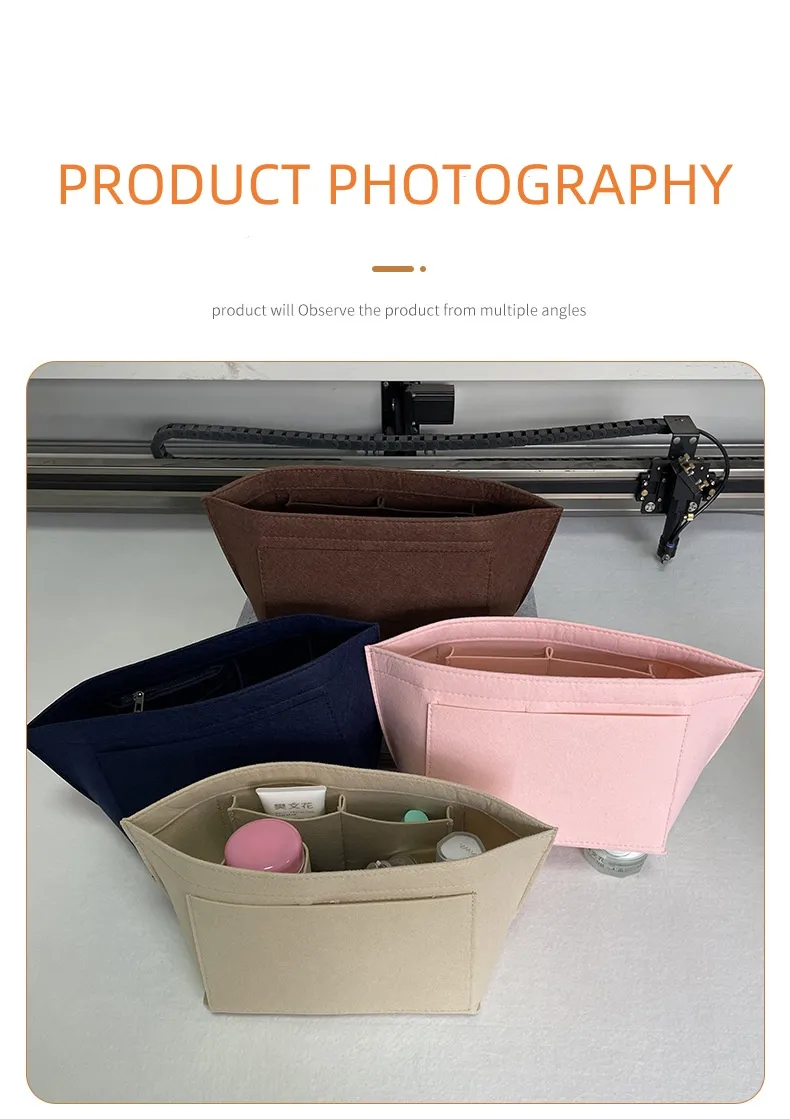

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024