industrial wool felt

Understanding Industrial Wool Felt Versatility and Applications

Industrial wool felt is a unique and versatile material that has been utilized in various manufacturing and production processes for centuries. Known for its durability, insulation properties, and ease of use, wool felt is composed of tightly compressed wool fibers that are processed to create a dense, mat-like structure. This material is not only eco-friendly but also offers a range of applications across multiple industries, making it an invaluable resource.

One of the most notable characteristics of industrial wool felt is its excellent thermal insulation properties. The natural crimp of wool fibers creates air pockets that trap heat, making it an ideal choice for thermal insulation in construction and automotive industries. In buildings, wool felt can be used in walls and roofs to enhance energy efficiency, reducing heating and cooling costs. In the automotive sector, this felt is often found in soundproofing applications, muffling engine noise and providing a more comfortable ride for occupants.

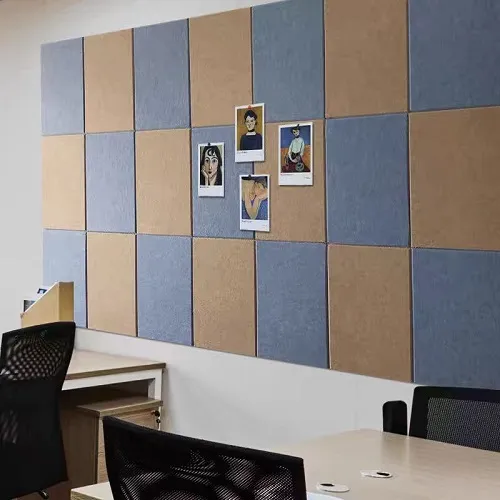

Moreover, wool felt is known for its acoustic properties. Its dense structure effectively absorbs sound waves, making it a popular material for sound insulation in offices, concert halls, and recording studios. By minimizing noise pollution, wool felt enhances environmental quality and contributes to better productivity in workspaces and improved auditory experiences in performance venues.

Another key attribute of industrial wool felt is its resilience and robustness. It can withstand significant wear and tear, making it suitable for various applications, including flooring, padding, and industrial components. For instance, manufacturers use wool felt as cushioning material in packaging to protect delicate items during transport. Its durability ensures that products remain intact while minimizing waste, thereby supporting sustainable manufacturing practices.

industrial wool felt

Additionally, industrial wool felt is an excellent choice for crafting functional and aesthetic products. In the fashion and accessories sector, designers utilize wool felt to create bags, hats, and decorative items. The fabric's versatility in color and texture allows for creative designs while maintaining the quality that consumers demand. Even in the arts, wool felt serves as a popular medium for creating unique artworks and installations, showcasing its appeal beyond traditional industrial uses.

Wool felt is also naturally fire-resistant and resistant to mold and mildew, further enhancing its safety and longevity in various applications. This makes it particularly useful in settings where fire safety is paramount, such as theatres and public buildings.

As sustainability becomes increasingly important in manufacturing, wool felt stands out as a renewable resource. Sourced from sheep, it is biodegradable and can decompose over time, reducing environmental impact compared to synthetic materials. The wool industry is committed to ethical practices, ensuring that the production of wool felt aligns with eco-friendly principles.

In conclusion, industrial wool felt is a remarkable material that combines functionality and sustainability. Its wide-ranging applications—from thermal and acoustic insulation to cushioning and fashion items—underscore its value across multiple sectors. As industries continue to seek sustainable materials that perform well under various conditions, the demand for industrial wool felt is likely to grow, paving the way for further innovations and developments in this versatile resource.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024