Feb . 16, 2025 13:52

Back to list

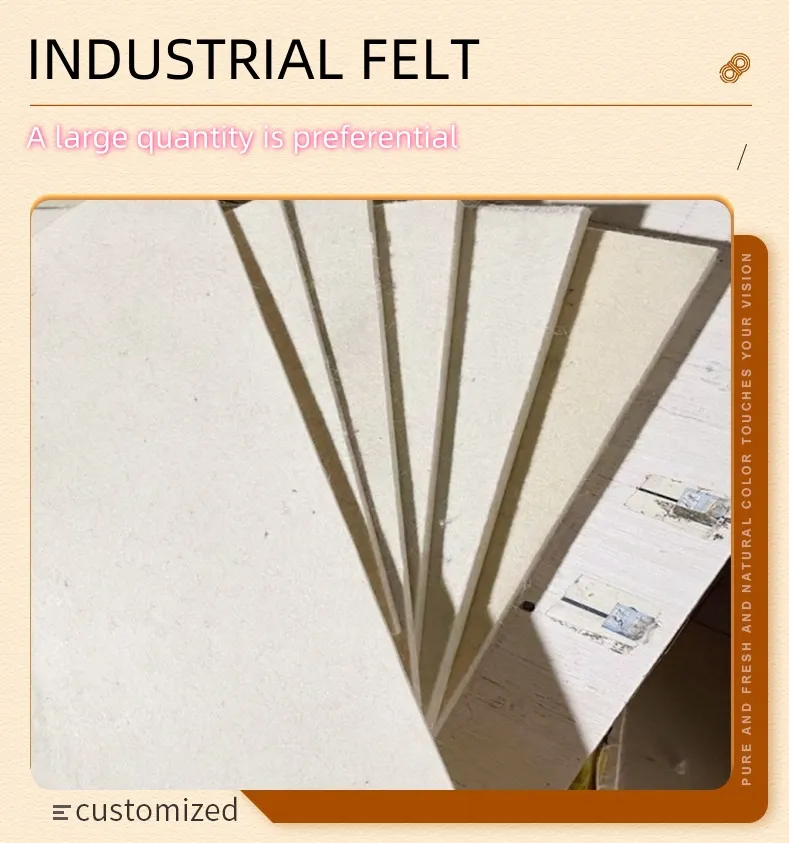

industrial felt

Industrial felt, a seemingly simple material, plays a critical role across various sectors due to its unique properties. This unique fabric, often underestimated, is crafted from natural and synthetic fibers that are pressed and condensed to achieve the desired thickness and density. Understanding the complexities and applications of industrial felt can enhance its implementation and optimize its use in diverse fields.

The expertise behind industrial felt manufacturing involves meticulous attention to detail, ensuring the fabric’s thickness, density, and texture meet specific industry requirements. Manufacturers employ sophisticated machinery to achieve precise control over these variables, guaranteeing a high-quality product that meets client expectations. This precision ensures that felt can seamlessly integrate into existing systems, delivering consistent performance and reliability. Trustworthiness in industrial felt utilization stems from its proven track record. Industries have relied on felt for decades, validating its performance and adaptability. The continued research and development efforts by manufacturers ensure that felt remains at the forefront of industrial innovation. This ongoing investment in improvement solidifies felt’s reputation as a trustworthy material that meets the evolving demands of diverse industries. Professionals using industrial felt often draw from extensive experience, having witnessed its evolution and diverse applications. This experience boosts confidence in selecting felt for various projects, knowing it will meet the required specifications and withstand operational demands. These experiences, coupled with expert knowledge, contribute significantly to the decision-making processes in industries seeking efficient and reliable materials. The authority of industrial felt, therefore, is not solely based on its historical use but also on its ability to adapt and cater to modern industrial challenges. The material’s authoritative status is reinforced by the endorsements from industries that continually seek its benefits for innovative applications. Its myriad uses and the continuous endorsement from industry veterans underscore its indispensable role across sectors. In conclusion, industrial felt is more than just a material; it is a versatile, reliable, and sustainable solution integral to the advancement of myriad industries. Its exceptional properties and adaptability continue to make it a preferred choice, with its use only limited by the creativity of professionals. For businesses looking to integrate efficient and effective materials, industrial felt promises unmatched performance and an opportunity to innovate within their respective industries.

The expertise behind industrial felt manufacturing involves meticulous attention to detail, ensuring the fabric’s thickness, density, and texture meet specific industry requirements. Manufacturers employ sophisticated machinery to achieve precise control over these variables, guaranteeing a high-quality product that meets client expectations. This precision ensures that felt can seamlessly integrate into existing systems, delivering consistent performance and reliability. Trustworthiness in industrial felt utilization stems from its proven track record. Industries have relied on felt for decades, validating its performance and adaptability. The continued research and development efforts by manufacturers ensure that felt remains at the forefront of industrial innovation. This ongoing investment in improvement solidifies felt’s reputation as a trustworthy material that meets the evolving demands of diverse industries. Professionals using industrial felt often draw from extensive experience, having witnessed its evolution and diverse applications. This experience boosts confidence in selecting felt for various projects, knowing it will meet the required specifications and withstand operational demands. These experiences, coupled with expert knowledge, contribute significantly to the decision-making processes in industries seeking efficient and reliable materials. The authority of industrial felt, therefore, is not solely based on its historical use but also on its ability to adapt and cater to modern industrial challenges. The material’s authoritative status is reinforced by the endorsements from industries that continually seek its benefits for innovative applications. Its myriad uses and the continuous endorsement from industry veterans underscore its indispensable role across sectors. In conclusion, industrial felt is more than just a material; it is a versatile, reliable, and sustainable solution integral to the advancement of myriad industries. Its exceptional properties and adaptability continue to make it a preferred choice, with its use only limited by the creativity of professionals. For businesses looking to integrate efficient and effective materials, industrial felt promises unmatched performance and an opportunity to innovate within their respective industries.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024