industrial felt manufacturers

The Landscape of Industrial Felt Manufacturers

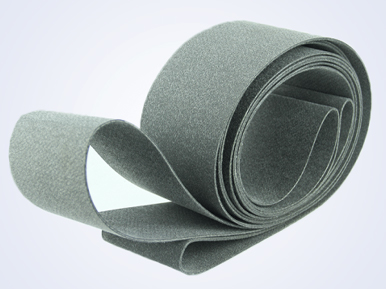

Industrial felt is a versatile and essential material used in various applications across multiple industries, including automotive, textile, electronics, and construction. As the demand for high-quality felt products continues to grow, industrial felt manufacturers are playing a critical role in meeting the diverse needs of their clients. This article aims to explore the landscape of industrial felt manufacturers, their production processes, and the importance of quality standards in this sector.

Industrial felt is made from combed fibers that are densely packed and compressed to create a thick, durable material. The manufacturing process typically involves several steps, including fiber selection, blending, carding, needling, and finishing. Each step is crucial in determining the final characteristics of the felt, such as thickness, density, and texture. Manufacturers often use various fibers, including wool, polyester, and acrylic, allowing them to produce felt products with different properties such as heat resistance, moisture absorption, and sound insulation.

The choice of materials is critical for industrial felt manufacturers. For instance, wool felt is known for its acoustic properties and is often used in soundproofing applications. On the other hand, synthetic felt made from polyester is commonly employed in the automotive industry due to its durability and resistance to water and chemicals. As manufacturers innovate and invest in research and development, they are continuously improving their products to meet the evolving needs of industries.

industrial felt manufacturers

In recent years, the industrial felt market has seen significant growth, driven by advancements in technology and an increasing focus on sustainability. Manufacturers are exploring eco-friendly materials and production processes that minimize environmental impact. This trend towards sustainability is not only beneficial for the planet but also enhances the marketability of felt products as consumers and businesses alike become more environmentally conscious.

Quality assurance is another vital aspect of industrial felt manufacturing. Manufacturers must adhere to stringent quality standards to ensure that their products meet industry specifications and customer requirements. This includes conducting regular testing for parameters such as density, thickness, and tensile strength. Certifications, such as ISO, play a crucial role in assuring clients of the quality and safety of the products they are purchasing.

The global nature of the industrial felt market means that manufacturers must also be aware of international trends and competition. Companies are increasingly looking to expand their reach beyond local markets and tap into international demand. This has led to a rise in collaborations and partnerships between manufacturers to share technology, expertise, and resources. In this competitive landscape, companies that invest in innovation and maintain high-quality standards will likely emerge as leaders.

In conclusion, industrial felt manufacturers are essential players in various sectors, providing critical materials that enhance product performance and functionality. With an increasing focus on sustainability, innovation, and quality assurance, these manufacturers are well-positioned to meet the challenges of a rapidly changing market. As they continue to evolve and adapt, the future looks bright for the industrial felt industry and the manufacturers behind it. These companies not only contribute to economic growth but also play a vital role in advancing technology and sustainability in manufacturing.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024