Top Manufacturers of Industrial Felt for Various Applications and Industries

The Landscape of Industrial Felt Manufacturers A Comprehensive Overview

Industrial felt, a versatile material known for its durability, insulation properties, and filtering capabilities, has carved out a significant niche in various industries. From automotive applications to construction and beyond, the demand for high-quality industrial felt has led to the emergence of numerous manufacturers specializing in this essential product. This article aims to explore the key features of industrial felt, its applications, and the role of manufacturers in meeting market needs.

Understanding Industrial Felt

Industrial felt is made from a blend of natural and synthetic fibers that are compressed and matted together, often using heat and moisture. This process creates a dense material with unique properties. Among its many qualities are thermal resistance, sound absorption, chemical resistance, and flexibility, making it suitable for various applications ranging from insulation to buffering and padding.

Applications of Industrial Felt

One of the most significant areas of application for industrial felt is in the automotive sector. Here, it is used for sound dampening, thermal insulation, and as a cushioning material in vehicle interiors. Felt mats and pads help reduce noise and vibration, enhancing comfort and safety for passengers.

In the construction industry, industrial felt plays a pivotal role in roofing and flooring solutions. Felt is commonly used as an underlayment in roofing applications to provide moisture protection. In flooring, felt pads are used under carpets and tiles to improve sound insulation and provide a softer underfoot experience.

Felt is also widely utilized in machinery and equipment. For example, felt seals and gaskets are essential in various machines to prevent moisture and dirt ingress. The textile's properties make it an ideal choice for absorbing vibrations, which can prolong the lifespan of machinery components.

The Role of Manufacturers

industrial felt manufacturers

Industrial felt manufacturers are at the heart of this sector, providing a diverse range of products tailored to meet specific industry needs. These manufacturers invest in research and development to create felt solutions with enhanced performance characteristics, such as greater resilience, improved thermal efficiency, or specific compliance with industry standards.

When selecting a manufacturer, businesses should consider several factors, including the range of products offered, manufacturing capabilities, quality control processes, and environmental sustainability practices. Leading manufacturers often adopt eco-friendly practices, employing recycled materials and sustainable production methods to reduce their environmental footprint.

Moreover, advanced manufacturing technologies, such as automation and precision cutting, enable manufacturers to produce felt with specific dimensions and properties, catering to bespoke requirements. This flexibility allows them to serve a broad spectrum of industries effectively, from small-scale applications to large industrial projects.

Challenges and Opportunities

The industrial felt manufacturing sector faces challenges such as market fluctuations, competition from alternative materials, and the rising demand for sustainable products. However, these challenges also present opportunities for manufacturers willing to innovate. By developing new formulations or integrating technological advancements, they can create high-performance felt that meets the evolving requirements of their customers.

Additionally, globalization has opened doors for manufacturers to access international markets. Exporting products allows manufacturers to broaden their customer base and mitigate risks associated with domestic market fluctuations. Furthermore, collaborations with industry stakeholders can lead to advancements in product offerings and shared knowledge about emerging trends.

Conclusion

The industrial felt manufacturing landscape is dynamic and diverse, reflecting the wide-ranging applications and importance of this material in various sectors. As manufacturers continue to innovate and adapt to market trends, industrial felt will remain a fundamental component in countless applications. Companies looking for reliable and high-quality felt solutions must choose their manufacturers wisely, considering factors such as quality, sustainability, and responsiveness to market needs. The future of industrial felt is promising, with innovation paving the way for even more versatile and efficient applications.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

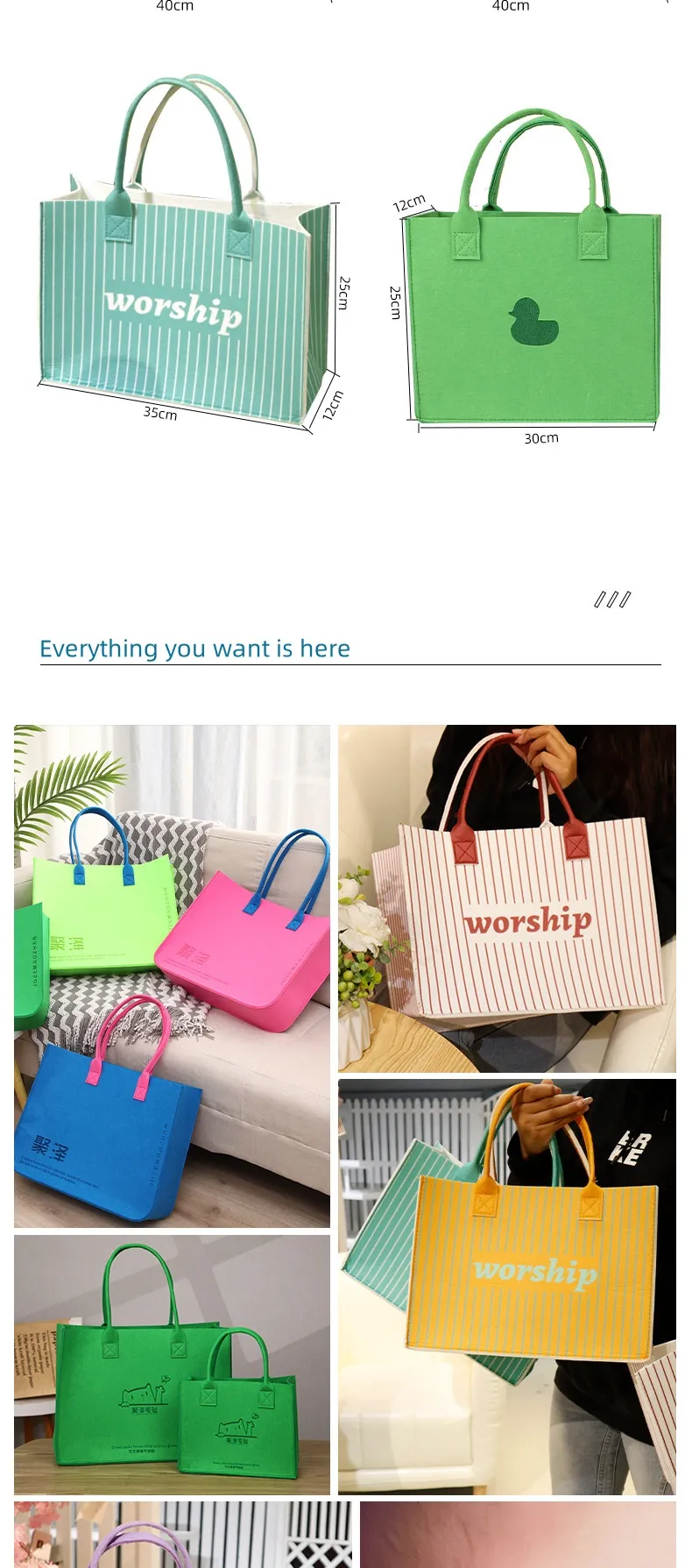

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024