Exploring the Versatility and Applications of Machinery Felt in Industrial Settings

The Versatility and Applications of Machinery Felt

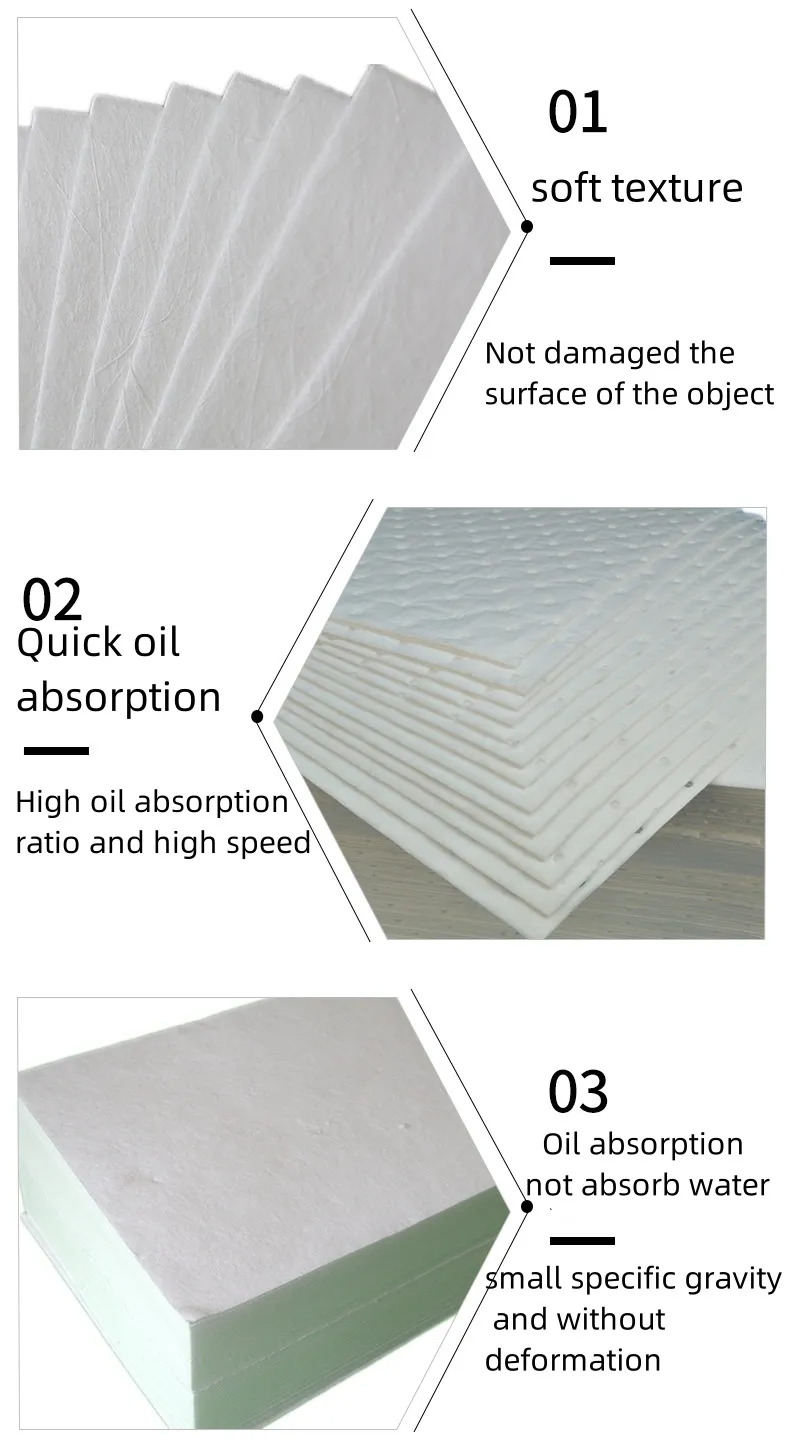

Machinery felt, an often overlooked yet essential material in various industrial applications, serves a multitude of functions that enhance the efficiency and effectiveness of machinery. This specialized felt, made from natural fibers (like wool) or synthetic materials (like polyester or nylon), is characterized by its durability, compressibility, and sound-dampening properties. With a diverse array of applications, machinery felt plays a critical role in industries ranging from manufacturing to automotive and even in the textile sector itself.

One of the primary uses of machinery felt is in the manufacturing of machinery components where it functions as a cushioning material. It effectively absorbs shock and vibration, providing vital protection for delicate parts during operation. For example, in the packaging machinery industry, felt pads are used under heavy machinery to cushion vibrations that could otherwise lead to wear and tear or even catastrophic failures. By dampening these vibrations, machinery felt helps ensure the longevity of equipment and reduces maintenance costs.

In addition to its cushioning properties, machinery felt excels in thermal insulation applications. Machinery that operates at high temperatures requires reliable insulation materials to maintain optimal operating conditions. Machinery felt's ability to withstand heat makes it ideal for use in applications like furnace linings or insulation for heating systems in manufacturing plants. Furthermore, its thermal insulation properties help maintain energy efficiency, crucial in industries that deal with power-saving measures and regulations.

Machinery felt also plays a significant role in the automotive sector, where it is utilized in soundproofing. Vehicles require a degree of sound insulation to ensure passenger comfort and compliance with noise regulations. Felt materials are strategically placed in areas such as the firewall, under the hood, and within the cabin to dampen noise from the engine, road, and wind. The sound-absorbing qualities of machinery felt help create a quieter and more pleasant driving experience.

machinery felt

Beyond mechanical applications, machinery felt is also employed in various textile manufacturing processes. In textile mills, it is used as a working surface for fabric production. The non-slip and cushioning properties of felt provide a stable platform on which delicate fabrics can be processed without risk of damage. In addition, it serves a role in the pressing and finishing stages of textile manufacturing, where steady pressure and smooth handling of materials are essential.

The adaptability of machinery felt extends to its use in construction as well. In building projects, machinery felt can be employed as a barrier against dust and moisture, protecting both workers and machinery from contamination. This is particularly important in construction zones where exposure to debris and environmental conditions can lead to costly delays and damages.

Another notable application is in the realm of crafting and design. Craftsmen utilize machinery felt in artistic endeavors, producing everything from intricate designs in fashion accessories to functional items like coasters and pads for furniture. Its versatility allows for a range of creative applications, making it a favored material in both industrial and artistic contexts.

Moreover, the sustainability aspect of machinery felt is gaining prominence, especially in light of growing environmental concerns. With a strong push towards eco-friendly materials, felt made from recycled fibers or sustainable sources is becoming increasingly popular. Manufacturers are recognizing the importance of incorporating sustainable practices, and felt can provide a green alternative to traditional materials used in machinery.

In summary, the significance of machinery felt in a multitude of industries cannot be understated. From cushioning and insulation to soundproofing and sustainable crafting solutions, its applications are as diverse as they are essential. As industries continue to evolve and seek more efficient methods and sustainable materials, machinery felt will likely play an even more critical role in the future, proving that this humble material is indeed a powerhouse in the machinery world. Whether in enhancing the operational efficiency of machines or serving artistic purposes, machinery felt exemplifies the blend of utility and creativity that modern industries strive to achieve.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024