Jan . 16, 2025 05:37

Back to list

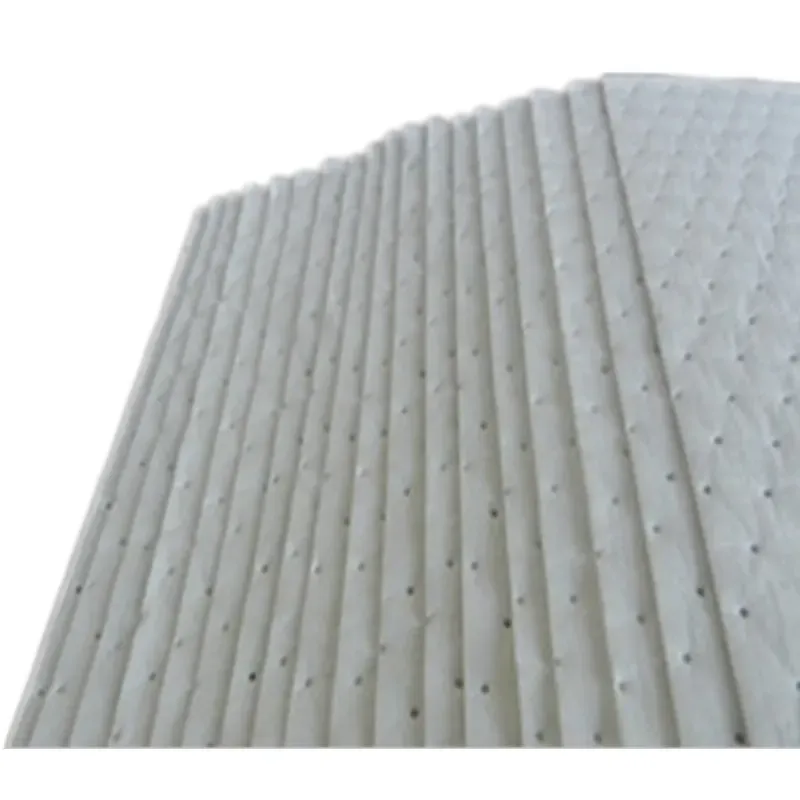

Color Felt Non-Woven Color Felt

Non-woven felt, a versatile and integral component across various industries, boasts distinct advantages over traditional materials. Its ascent in popularity is attributed not only to its adaptability but also to its superior functional properties.

From a durability standpoint, non-woven felt exhibits impressive resistance to wear and tear. This makes it a preferred choice for products that require long-lasting materials, such as filters and geotextiles. These applications benefit from the felt's breathability and moisture resistance, ensuring longevity and performance stability in challenging environments. Notably, the healthcare industry also benefits from the advantageous properties of non-woven felt. In medical applications, where hygiene and sterility are paramount, non-woven felt is utilized in the production of disposable items such as hospital gowns, masks, and surgical drapes. The fabric's ability to provide significant bacteria and pathogen barriers, while remaining lightweight and comfortable, underlines its importance in enhancing patient and practitioner safety. Furthermore, the fashion and creative industries have witnessed a surge in the utilization of non-woven felt. Designers value its versatility in creating innovative textures and layers without compromising comfort or functionality. Its availability in various colors and finishes offers endless possibilities for creative expression, from avant-garde fashion pieces to functional design elements in interior decor. In summary, non-woven felt's rise in various fields emanates from its combination of sustainability, versatility, and high-performance capabilities. Its role in advancing industry standards is underscored by its adaptability to meet specific needs while adhering to environmental and health regulations. As industries evolve, the demand for such innovative materials will continue to scale, solidifying non-woven felt's status as a material of choice for the modern era.

From a durability standpoint, non-woven felt exhibits impressive resistance to wear and tear. This makes it a preferred choice for products that require long-lasting materials, such as filters and geotextiles. These applications benefit from the felt's breathability and moisture resistance, ensuring longevity and performance stability in challenging environments. Notably, the healthcare industry also benefits from the advantageous properties of non-woven felt. In medical applications, where hygiene and sterility are paramount, non-woven felt is utilized in the production of disposable items such as hospital gowns, masks, and surgical drapes. The fabric's ability to provide significant bacteria and pathogen barriers, while remaining lightweight and comfortable, underlines its importance in enhancing patient and practitioner safety. Furthermore, the fashion and creative industries have witnessed a surge in the utilization of non-woven felt. Designers value its versatility in creating innovative textures and layers without compromising comfort or functionality. Its availability in various colors and finishes offers endless possibilities for creative expression, from avant-garde fashion pieces to functional design elements in interior decor. In summary, non-woven felt's rise in various fields emanates from its combination of sustainability, versatility, and high-performance capabilities. Its role in advancing industry standards is underscored by its adaptability to meet specific needs while adhering to environmental and health regulations. As industries evolve, the demand for such innovative materials will continue to scale, solidifying non-woven felt's status as a material of choice for the modern era.

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024