non woven needle felt

The Versatility and Applications of Non-Woven Needle Felt

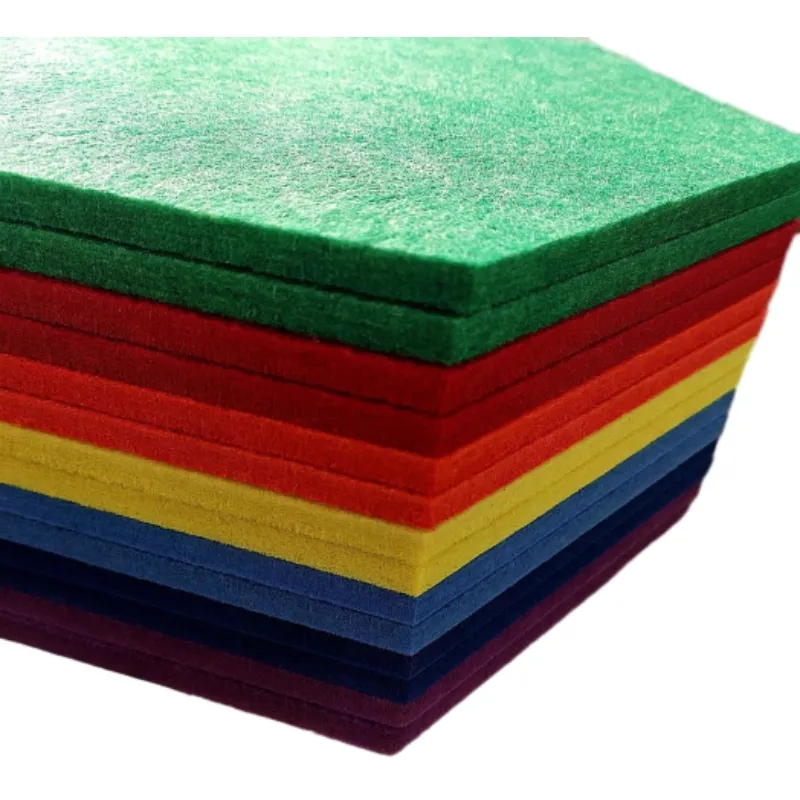

Non-woven needle felt is an innovative material that has gained significant traction in various industries due to its unique properties and versatility. This type of felt is created through a process that involves entangling fibers together using barbed needles, resulting in a dense and durable fabric. In this article, we will explore the characteristics, production methods, and diverse applications of non-woven needle felt.

Characteristics of Non-Woven Needle Felt

Non-woven needle felt stands out for several reasons. First and foremost, its manufacturing process enables the creation of a fabric that is both strong and lightweight. The entangled fibers provide excellent structural integrity, making it ideal for applications where durability is paramount. Moreover, the needle felting process offers advantages such as the ability to incorporate a variety of fibers, including natural and synthetic options, which can enhance the felt’s performance properties such as thermal insulation, sound absorption, and filtration.

Another significant characteristic of non-woven needle felt is its versatility in terms of thickness and texture. By adjusting the needle felting process, manufacturers can produce anything from thick, plush felts to thinner, more rigid versions. This flexibility allows for customization according to specific requirements, making it suitable for a wide range of applications across different sectors.

Production Process

The production of non-woven needle felt involves several key steps. Initially, raw fibers are selected based on the desired characteristics of the final product. These fibers can include wool, polyester, polypropylene, and others, depending on the application. Once the fibers are chosen, they are fed into a carding machine, which separates and aligns the fibers to prepare them for the felting process.

Following carding, the aligned fibers are laid out in a predetermined orientation and then subjected to the needle punching process. This step involves using barbed needles to repeatedly poke through the fiber mat, entangling the fibers together and creating a cohesive fabric. The entanglement process occurs in multiple stages, allowing manufacturers to control the density and thickness of the felt.

non woven needle felt

Finally, the needle felt may undergo further treatments, such as washing or coating, to enhance specific properties like water resistance or flame retardance. This thorough production process results in a material that meets high-quality standards and can be tailored to exact specifications.

Applications of Non-Woven Needle Felt

Non-woven needle felt finds applications in a wide array of industries, showcasing its remarkable versatility. One prominent use is in the automotive sector, where it serves as sound insulation, carpet backing, and even upholstery. The ability of needle felt to dampen sound and provide thermal insulation makes it an excellent choice for improving passenger comfort in vehicles.

Another significant application of non-woven needle felt is in the filtration industry. Due to its dense structure, it can effectively filter particulates from air and liquids. This property makes it ideal for use in HVAC systems, water treatment facilities, and various industrial filtration processes.

In the realm of healthcare, non-woven needle felt is used in surgical drapes, gowns, and other medical textiles. The fabric’s ability to be sterilized and its resistance to fluids make it a reliable choice for maintaining hygiene in medical settings.

Additionally, the craft and textile industries utilize non-woven needle felt for its aesthetic appeal and ease of use in arts and crafts projects. The material can be dyed in various colors and patterns, allowing for creative applications in fashion, home décor, and other artistic endeavors.

Conclusion

In summary, non-woven needle felt is a remarkable material with a broad range of applications, from automotive and filtration to healthcare and crafts. Its unique production process, which allows for customization in terms of thickness, texture, and fiber composition, makes it an invaluable resource in numerous industries. As technology continues to evolve and new applications are discovered, the importance of non-woven needle felt is likely to increase, solidifying its place as a vital material in modern manufacturing practices.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024