High-Quality Oil Absorbent Felt for Effective Spill Management

Understanding Oil Absorbent Felt A Vital Tool for Spill Management

In various industries, managing spills and leaks is a critical aspect of maintaining safety and environmental integrity. One such tool that has gained substantial attention for its effectiveness in dealing with oil spills is oil absorbent felt. This innovative material has become an indispensable part of spill cleanup strategies, allowing companies to mitigate environmental hazards swiftly and efficiently.

Oil absorbent felt is typically made from synthetic fibers that are specially designed to attract and absorb oil while repelling water. This unique property makes it particularly useful in environments where oil spills may occur, such as in industrial settings, automotive shops, and on oil rigs. The primary advantage of using oil absorbent felt is its high absorbent capacity; it can soak up many times its weight in oil, thus quickly addressing potential environmental disasters.

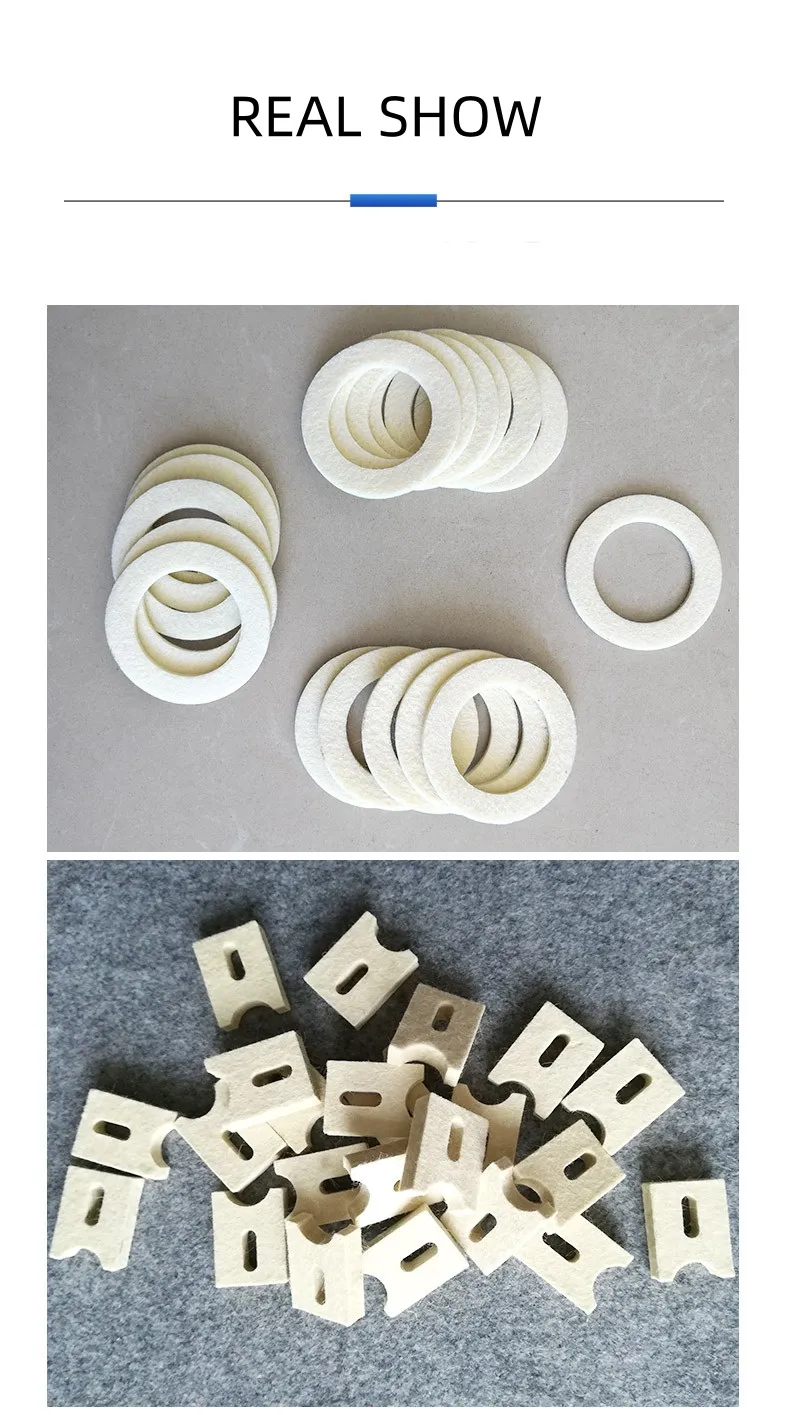

One of the critical features of oil absorbent felt is its versatility. It can be easily cut into different shapes and sizes, allowing it to be tailored for various applications. Whether used in large sheets for extensive coverage or smaller pads for targeted absorption, oil absorbent felt can adapt to the specific needs of a cleanup operation. Additionally, it can be employed in both indoor and outdoor settings, making it a go-to solution for a wide range of industries.

The environmental impact of oil spills is profound, affecting marine life, ecosystems, and even human health. The immediate response to a spill is crucial in minimizing these impacts, and oil absorbent felt plays a significant role in this crucial first step. When placed on the spill site, the felt quickly absorbs the free-floating oil, preventing it from spreading further and allowing for easier cleanup. This not only protects wildlife but also aids in compliance with environmental regulations that require timely and effective spill response.

oil absorbent felt

Furthermore, oil absorbent felt is designed to be durable and resilient. Many types can endure harsh conditions, such as extreme temperatures and abrasive surfaces, making them suitable for various industrial applications. This durability ensures that they can be reliable partners in spill response, ready to perform when needed the most.

In addition to its effectiveness and versatility, oil absorbent felt is also a cost-effective solution for spill management. The ability to absorb large volumes of oil allows organizations to minimize waste and reduce the costs associated with extensive cleanup efforts. Moreover, many manufacturers are developing eco-friendly options, which align with increasing corporate sustainability goals.

Finally, training and education are essential when it comes to the effective use of oil absorbent felt. Personnel must be familiar with the different types of absorbent materials available and understand how to deploy them correctly during a spill. Proper training ensures that organizations are prepared to respond effectively, minimizing damage and helping protect the environment.

In conclusion, oil absorbent felt is a crucial tool in spill management, combining high absorbency, versatility, and durability to address oil spills efficiently. Its significant environmental importance, along with the potential for cost savings, makes it an essential component for industries that handle oil. As the world continues to prioritize environmental responsibility, the role of oil absorbent felt will only continue to grow.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024