the Versatile Applications and Benefits of Industrial Felt in Various Industries and Crafts

Exploring the Versatile Applications and Benefits of Industrial Felt in Various Industries and Crafts

The Versatility and Applications of Industrial Felt

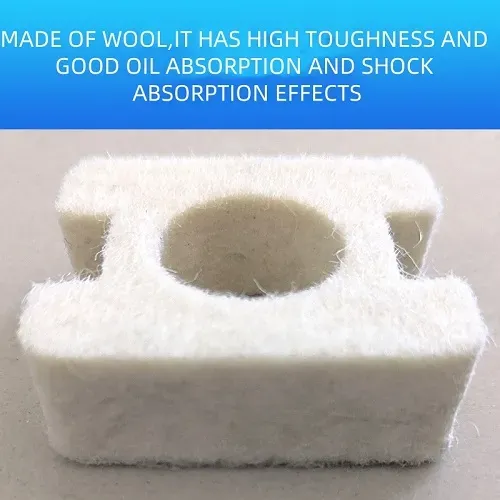

Industrial felt is a specialized material that has gained significant traction across various industries due to its unique properties and versatility. Composed mainly of wool, synthetic fibers, or a combination of materials, industrial felt is renowned for its durability, resilience, and insulating qualities. This article will explore the characteristics of industrial felt, its manufacturing process, and its numerous applications in modern industry.

Characteristics of Industrial Felt

One of the standout features of industrial felt is its ability to absorb sound and vibrations, making it an ideal choice for a wide range of applications where noise reduction is necessary. Additionally, industrial felt is non-conductive, meaning it can effectively insulate against heat and electricity. Its compressibility allows it to maintain shape and provide cushioning, making it suitable for use in high-impact environments.

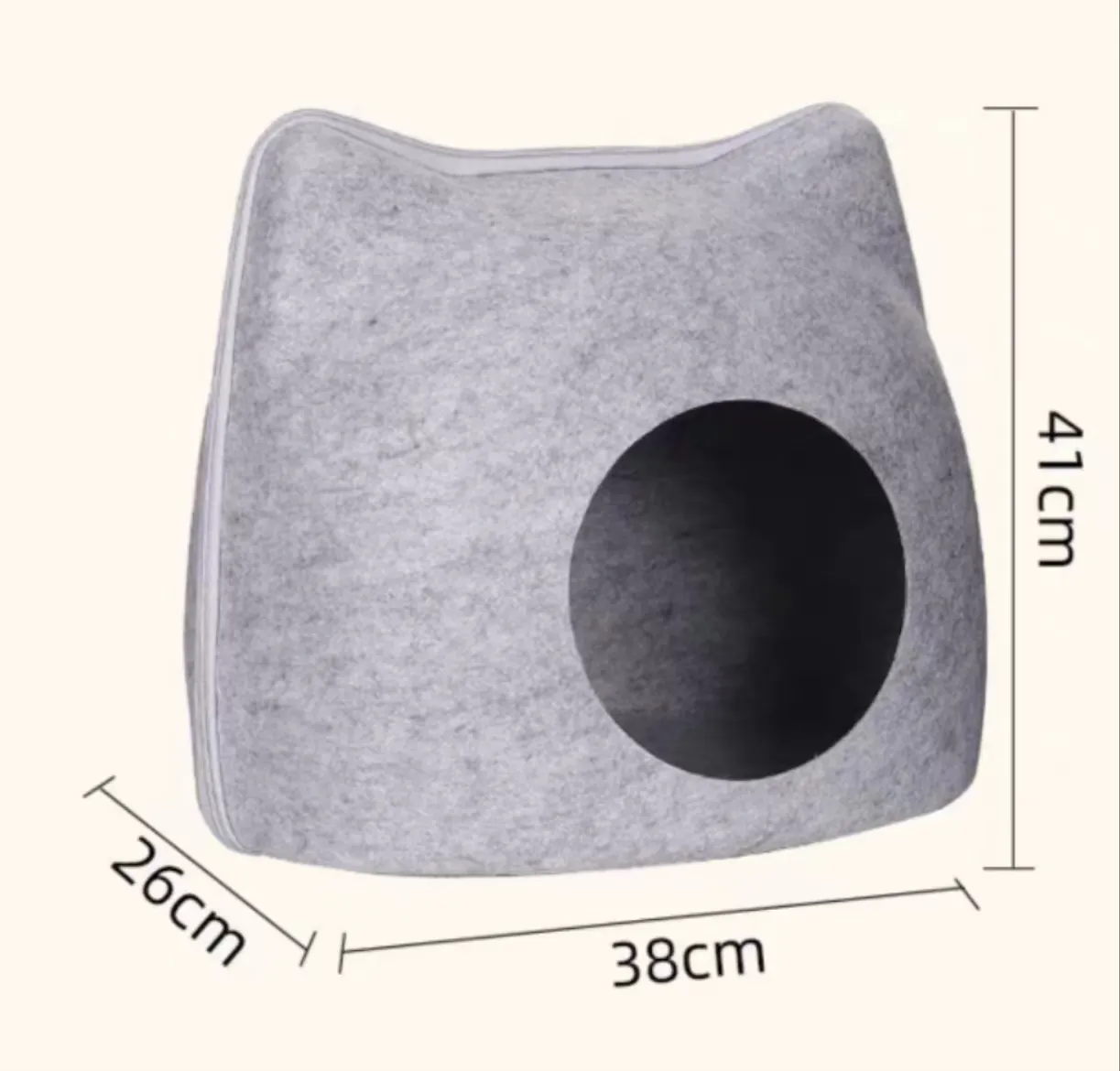

Moreover, the material can be produced in various densities and thicknesses, tailoring it to specific needs. The fine structure of felted fibers enhances its flexibility, allowing it to be easily shaped and cut into desired forms without fraying. These characteristics highlight the adaptability of industrial felt for different tasks across diverse sectors.

Colored Felt

Manufacturing Process

The production of industrial felt involves a wet or dry felting process. In the wet felting method, layers of fibers are intermingled with moisture and agitation to create a dense mat. Conversely, dry felting employs a mechanical method to entangle fibers through the use of needles, producing a robust and compact felt structure. Both methods result in a non-woven fabric that can be further finished for specific applications, such as dyeing or adding protective coatings.

Quality control is paramount during the manufacturing process to ensure the final product meets industry standards. Factors such as fiber type, thickness, and density are critically assessed to guarantee that the felt exhibits the desired attributes for its intended use.

industrial felt

Applications in Industry

Industrial felt is utilized across a myriad of industries, showcasing its adaptability and functionality. In the automotive sector, felt is often used for noise and vibration dampening in vehicle interiors, contributing to a more serene driving experience. Its cushioning properties also make it suitable for gaskets and seals, enhancing the performance of various mechanical components.

Moreover, in the textile and fashion industry, felt is favored for the production of high-quality garments, accessories, and even flooring materials. The ability to dye and shape felt allows designers to create innovative and visually appealing products.

In the machinery and manufacturing realm, industrial felt serves as an essential component in filtration systems. It is employed to filter liquids and air, ensuring that contaminants are removed effectively. Additionally, its use in padding and protective coverings helps safeguard sensitive equipment during transportation and handling, preventing damage from impacts.

Further, the use of industrial felt in the arts and crafts sector has also been on the rise, with many crafters appreciating its texture and ease of use for various projects, including quilts, ornaments, and sport products.

Conclusion

Industrial felt is a versatile and invaluable material in today's industrial landscape. Its unique properties, coupled with a robust manufacturing process, enable it to serve a multitude of applications across diverse sectors. From automotive to arts and crafts, its impact can be seen in everyday products, highlighting the importance of this material in fostering innovation and functionality in industry. As technology advances and industries evolve, the potential for industrial felt continues to expand, promising even greater applications in the future.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024