Feb . 20, 2025 09:00

Back to list

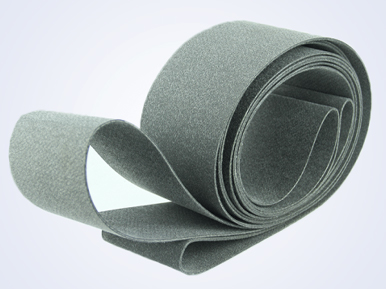

hard felt wheel

The trajectory of industrial tools and materials has seen a steady transformation as demands for efficiency, precision, and durability continue to evolve. Among these, the hard felt wheel emerges as a quintessential component in a myriad of applications. These dense, fibrous tools are not just popular for their versatility but are revered for their ability to enhance various manufacturing processes. Let’s delve deep into the unique aspects of hard felt wheels through personal experience, industry expertise, and authoritative insights to understand why they are indispensable.

Authoritative bodies within the manufacturing industry emphasize the importance of selecting the right type of hard felt wheel. There are variations based on density and hardness, each serving a distinct purpose. For instance, a denser wheel might be suitable for aggressive metal polishing, while a softer variant could be ideal for delicate glassworks. Adhering to the suggestions provided by industry leaders can dramatically enhance production quality and efficiency. Articles and guidelines published by recognized authorities in industrial manufacturing often highlight these choices, further bolstering the wheel's trusted reputation. The trustworthiness of hard felt wheels is not confined to their operation. It extends to their environmental impact as well. Many manufacturers now prioritize eco-friendly production methods, using natural fibers and ensuring that the wheels are recyclable. This sustainability aspect adds another layer of trust, especially for businesses striving for green certification and environmentally-conscious consumers. In essence, real-world experience, coupled with industry expertise and an understanding of authoritative guidelines, validates the hard felt wheel's indispensable role across various sectors. Whether through personal success stories or conference discussions, the consensus is clear hard felt wheels have firmly cemented their place as a tool of choice for tasks requiring precision, durability, and sustainability. As technology and industry standards evolve, the adaptability and reliability of hard felt wheels ensure they continue to meet new challenges head-on, retaining their critical status in workshops and factories worldwide.

Authoritative bodies within the manufacturing industry emphasize the importance of selecting the right type of hard felt wheel. There are variations based on density and hardness, each serving a distinct purpose. For instance, a denser wheel might be suitable for aggressive metal polishing, while a softer variant could be ideal for delicate glassworks. Adhering to the suggestions provided by industry leaders can dramatically enhance production quality and efficiency. Articles and guidelines published by recognized authorities in industrial manufacturing often highlight these choices, further bolstering the wheel's trusted reputation. The trustworthiness of hard felt wheels is not confined to their operation. It extends to their environmental impact as well. Many manufacturers now prioritize eco-friendly production methods, using natural fibers and ensuring that the wheels are recyclable. This sustainability aspect adds another layer of trust, especially for businesses striving for green certification and environmentally-conscious consumers. In essence, real-world experience, coupled with industry expertise and an understanding of authoritative guidelines, validates the hard felt wheel's indispensable role across various sectors. Whether through personal success stories or conference discussions, the consensus is clear hard felt wheels have firmly cemented their place as a tool of choice for tasks requiring precision, durability, and sustainability. As technology and industry standards evolve, the adaptability and reliability of hard felt wheels ensure they continue to meet new challenges head-on, retaining their critical status in workshops and factories worldwide.

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024