thick industrial felt

The Versatility and Applications of Thick Industrial Felt

Thick industrial felt is a robust material widely used across various industries for its unique properties and versatility. Made from compressed wool, synthetic fibers, or a blend of both, this durable material can withstand extreme conditions, making it an excellent choice for numerous applications. Its composition typically involves a high density, ensuring strength and longevity, and contributing to its substantial acoustic and thermal insulation capabilities.

Properties of Thick Industrial Felt

One of the primary characteristics of thick industrial felt is its density. The material is often produced in thicknesses ranging from a few millimeters to several centimeters, depending on the specific application requirements. This thickness not only provides durability but also enhances its insulation properties, making it ideal for applications where temperature control is critical.

Additionally, industrial felt is known for its ability to absorb shock and vibrations. This quality makes it particularly valuable in manufacturing settings, where machinery and heavy equipment frequently operate. By absorbing vibrations and shocks, thick industrial felt can help to extend the lifespan of machinery and improve overall operational efficiency.

Another notable property of industrial felt is its resistance to chemicals and moisture. Depending on the specific formulation, felt can withstand exposure to oils, solvents, and other hazardous substances, which is crucial in industrial environments. Furthermore, it does not easily harbor bacteria or mold, enhancing its suitability for environments requiring high hygiene standards.

Applications in Various Industries

thick industrial felt

1. Manufacturing In manufacturing, thick industrial felt is utilized as a cushioning material in assembly lines. It protects sensitive components during transit and assembly, preventing damage from impacts and vibrations. Additionally, it can provide thermal insulation around various machinery, reducing energy consumption and maintaining temperature control.

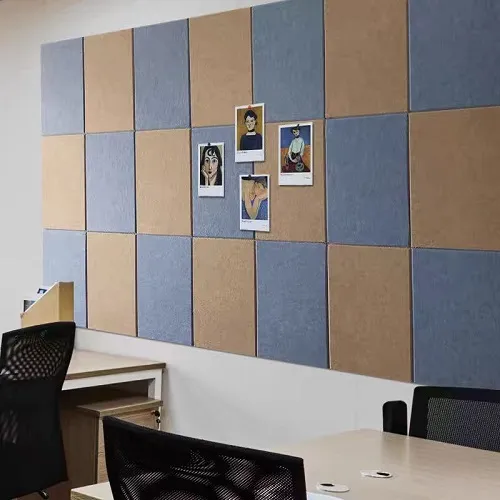

2. Construction In the construction sector, thick felt is often used for soundproofing and thermal insulation in walls, ceilings, and floors. Its ability to dampen sound makes it an excellent choice for residential and commercial buildings in noisy environments. Moreover, its moisture resistance contributes to preventing mold growth, which is a vital factor in maintaining the structural integrity of buildings.

3. Automotive The automotive industry also benefits from thick industrial felt. It is frequently used in sound insulation applications to reduce noise within vehicle interiors, enhancing passenger comfort. Additionally, felt can be used in gasket applications, providing a reliable seal while absorbing vibrations, thereby contributing to a smoother ride.

4. Textile Industry In the textile industry, thick industrial felt serves as a base material for various products, including handbags, shoes, and crafts. Its durability and aesthetic appeal make it a popular choice among designers and artisans looking for high-quality materials.

5. Arts and Crafts Beyond industrial applications, thick felt is widely embraced in the arts and crafts sphere. It is used for making decorative items, toys, and accessories. Artists appreciate its versatility and ease of handling, allowing for creative expression in various forms.

Conclusion

Thick industrial felt stands out as an incredibly versatile material that finds applications across a multitude of industries. Its unique properties, including durability, shock absorption, thermal and acoustic insulation, and resistance to chemicals, make it a prime candidate for both industrial and creative uses. As industries continue to evolve and seek innovative solutions, the demand for high-quality industrial felt is likely to grow, ensuring that this timeless material remains relevant in the modern age. Whether it’s in manufacturing, construction, automotive, or arts and crafts, thick industrial felt continues to play a significant role in enhancing functionality and efficiency.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024