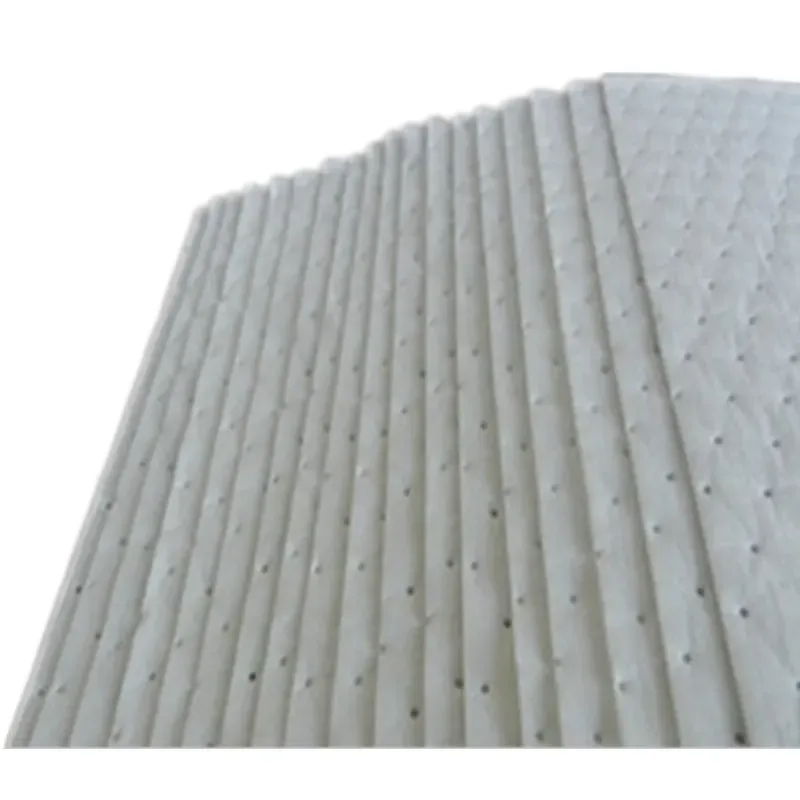

hard felt polishing wheel

The Versatility and Benefits of Hard Felt Polishing Wheels

Polishing is an essential process in various industries, ranging from metalworking to woodworking, as it improves the surface finish of materials, enhancing both aesthetic appeal and functional performance. Among the different tools available for polishing, hard felt polishing wheels have gained popularity due to their unique properties and versatility. This article explores the characteristics, applications, and advantages of hard felt polishing wheels, making them a valuable addition to any polishing toolkit.

What Are Hard Felt Polishing Wheels?

Hard felt polishing wheels are circular discs made from compressed wool fibers, designed to withstand higher pressures and provide enhanced durability during polishing operations. Unlike softer felt options, hard felt wheels are specifically engineered to maintain their shape and structure under intense friction, making them suitable for tasks that require a more aggressive polishing action. These wheels are typically mounted on various machines, such as rotary tools or bench grinders, facilitating efficient and uniform surface treatment.

Characteristics of Hard Felt Polishing Wheels

1. Durability Hard felt polishing wheels are constructed from dense wool fibers, giving them a robust structure that resists wear and deformation. This durability allows them to be used for more demanding polishing tasks without losing their effectiveness.

2. Versatility These wheels can be employed on a wide range of materials, including metals, plastics, wood, and ceramics. Their adaptability makes them a staple in many workshops and manufacturing facilities.

3. Variety of Grit Options Hard felt polishing wheels are available in different grit sizes, allowing users to select the appropriate wheel for specific polishing needs—whether it’s rough finishing or achieving a fine gloss.

4. Compatibility These wheels fit most types of polishing machines, making it easy for users to integrate them into their existing setups without the need for additional modifications.

Applications of Hard Felt Polishing Wheels

1. Metals In metalworking, hard felt polishing wheels excel in polishing stainless steel, aluminum, brass, and other metals. They can effectively remove oxidation, scale, and burrs, resulting in smooth, shiny finishes.

hard felt polishing wheel

2. Jewelry Making Jewelers utilize hard felt polishing wheels to achieve high luster on precious metals and gemstones. The fine polishing capabilities of these wheels allow artisans to enhance the visual appeal of their creations.

3. Automotive Industry In automotive detailing, hard felt polishing wheels are used to restore and maintain the shine of vehicle surfaces. They can polish headlights, rims, and exhaust tips, improving the overall appearance of the vehicle.

4. Woodworking Woodworkers employ hard felt wheels for polishing finished wood surfaces to achieve a smooth and polished look, enhancing the grain and finish quality of their products.

5. Electronics In electronics, these polishing wheels are used to polish components, ensuring that surfaces are smooth for both aesthetic reasons and to maintain proper functionality.

Advantages of Using Hard Felt Polishing Wheels

1. Efficiency The density and hardness of hard felt polishing wheels allow for quick and effective material removal. This efficiency can significantly reduce the time required to achieve desired finishes, enhancing overall productivity.

2. Consistent Results The uniform structure of hard felt wheels ensures that polishing is consistent across various applications. This reliability is crucial for industries where precision and quality are paramount.

3. Cost-Effective Given their durability, hard felt polishing wheels offer long service life before wear occurs, making them a cost-effective solution in the long run. Users can benefit from less frequent replacements, reducing operational costs.

4. Minimal Dust Generation Unlike some abrasive polishing methods, hard felt wheels produce minimal dust, leading to a cleaner work environment. This is particularly beneficial in settings where cleanliness and safety are vital.

Conclusion

Hard felt polishing wheels stand out as essential tools for anyone involved in polishing applications. Their unique properties, versatility, and efficiency make them a preferred choice across numerous industries, from metalworking to jewelry making. By investing in high-quality hard felt polishing wheels, users can achieve superior finish and durability while enjoying the benefits of reduced operational costs and cleaner workflows. Whether you are a hobbyist or a professional, integrating hard felt polishing wheels into your process can elevate the quality of your work.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024