Jan . 09, 2025 11:50

Back to list

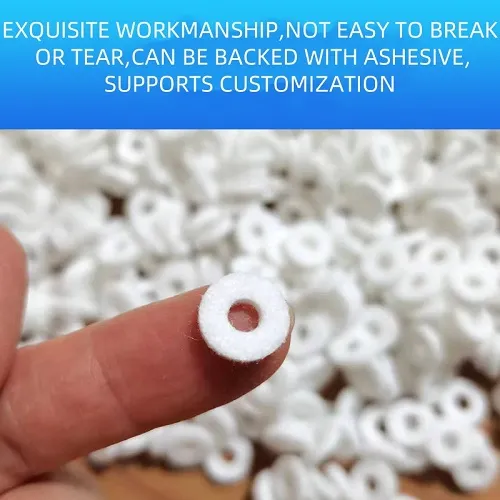

Color Felt Non-Woven Color Felt

As an individual with extensive experience in the textile industry, particularly in felt manufacturing, I am committed to sharing insights that reflect both my expertise and the broader market dynamics of this fascinating material. Felt, an ancient textile, has captivated both artisans and industrialists with its unique properties and versatility. My journey in exploring felt's multiple applications embodies a tapestry of artistic exploration and technical innovation, lending credibility to the knowledge shared here.

Credibility in the felt manufacturing industry is bolstered through continuous innovation and adherence to quality standards. The processes involved in felt production—from carding and blending to pressing and finishing—require precision and attention to detail. My role has often involved ensuring that every batch of felt meets stringent quality metrics, underscoring a commitment to excellence. Trust in our felt products is further established by rigorous testing and validation. Each product iteration undergoes thorough scrutiny to verify its integrity, resilience, and safety, aligning with international standards. This meticulous approach not only assures customers of the product's reliability but also fortifies the manufacturer's reputation as a trusted name in the field. In conclusion, the landscape of felt manufacturing is as rich and textured as the material itself. With a foundation rooted in tradition and an eye toward future innovation, felt manufacturers must navigate an evolving marketplace with a blend of expertise, authority, and integrity. My ongoing involvement in this industry exemplifies a dedication to mastering the intricacies of felt production and a fervent commitment to delivering products that resonate with quality and sustainability. This narrative not only serves as a comprehensive guide for fellow enthusiasts but also highlights the compelling promise felt holds for diverse applications across various sectors.

Credibility in the felt manufacturing industry is bolstered through continuous innovation and adherence to quality standards. The processes involved in felt production—from carding and blending to pressing and finishing—require precision and attention to detail. My role has often involved ensuring that every batch of felt meets stringent quality metrics, underscoring a commitment to excellence. Trust in our felt products is further established by rigorous testing and validation. Each product iteration undergoes thorough scrutiny to verify its integrity, resilience, and safety, aligning with international standards. This meticulous approach not only assures customers of the product's reliability but also fortifies the manufacturer's reputation as a trusted name in the field. In conclusion, the landscape of felt manufacturing is as rich and textured as the material itself. With a foundation rooted in tradition and an eye toward future innovation, felt manufacturers must navigate an evolving marketplace with a blend of expertise, authority, and integrity. My ongoing involvement in this industry exemplifies a dedication to mastering the intricacies of felt production and a fervent commitment to delivering products that resonate with quality and sustainability. This narrative not only serves as a comprehensive guide for fellow enthusiasts but also highlights the compelling promise felt holds for diverse applications across various sectors.

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024