Innovative Automotive Felt Fabric for Enhanced Vehicle Interiors and Comfort Solutions

The Importance of Automotive Felt Fabric in Modern Vehicle Manufacturing

In the automotive industry, every component matters, from the engine to the upholstery, contributing to the overall vehicle performance, comfort, and aesthetic appeal. One often-overlooked material that plays a vital role in vehicle manufacturing is automotive felt fabric. This versatile material has become increasingly important due to its unique characteristics and benefits, impacting not only the manufacturing process but also the everyday experience of vehicle owners.

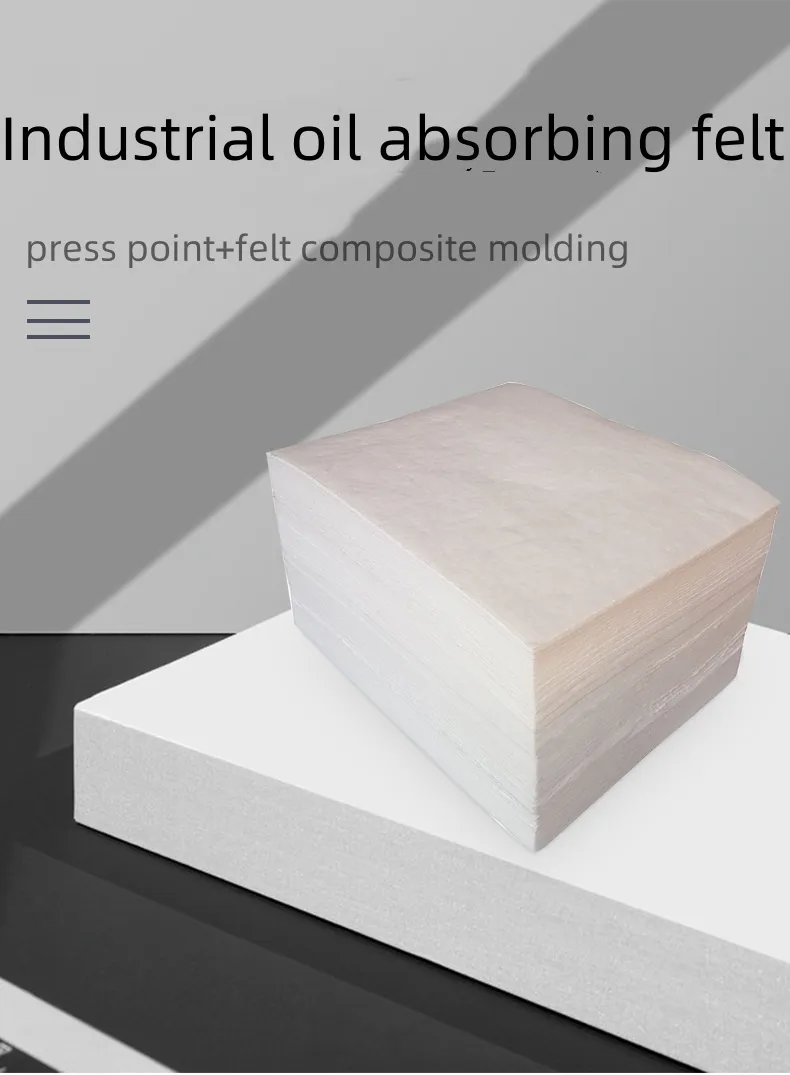

Automotive felt fabric, also known as automotive felt or nonwoven felt, is primarily made from natural or synthetic fibers that are bonded together using heat, pressure, or adhesive. This results in a dense, durable, and resilient material that meets the rigorous demands of the automotive environment. Its production process allows for flexibility in design, making it suitable for a variety of applications within a vehicle.

One of the most significant advantages of automotive felt fabric is its exceptional sound and vibration dampening properties. In modern vehicles, minimizing noise and vibration is crucial for enhancing the driving experience. Felt fabric is often used in areas like the floor, roof, and door linings, where it can effectively absorb sound waves and reduce unwanted noise. This not only contributes to a quieter cabin but also elevates the perceived quality and luxury of the vehicle, making it more appealing to consumers.

In addition to its soundproofing abilities, automotive felt fabric offers excellent thermal insulation. Many felt materials are designed to withstand high temperatures, making them suitable for use in engine compartments and other heat-intensive areas. By insulating vital components, automotive felt fabric helps maintain optimal operating temperatures and contributes to the overall energy efficiency of the vehicle. This is particularly important in electric vehicles (EVs), where thermal management plays a critical role in battery longevity and performance.

automotive felt fabric

The versatility of automotive felt fabric extends beyond sound and thermal insulation. It is also widely used as a protective layer for various components within the vehicle. For instance, under-hood applications utilize felt to shield delicate electrical parts from heat, vibrations, and debris. Similarly, it can line storage compartments and glove boxes, providing a soft surface that prevents damage to stored items. Additionally, felt fabric is used in interior applications such as headliners and acoustic panels, enhancing both functionality and aesthetic appeal.

Sustainability is another reason automotive felt fabric is gaining traction in the industry. Many manufacturers are leaning towards eco-friendly materials, and felt fabric can be produced from recycled fibers or biodegradable materials. The use of sustainable felt not only meets rising consumer demand for environmentally responsible products but also aligns with the automotive industry's shift towards greener practices. This focus on sustainability can resonate with consumers, influencing their purchasing decisions and fostering brand loyalty.

Moreover, the customizable nature of automotive felt fabric allows manufacturers to create tailored solutions that meet specific needs. Whether it's the thickness, density, or fiber composition, felt fabric can be engineered to meet the unique requirements of different vehicle models. This adaptability ensures that automotive manufacturers can deliver high-quality products that cater to the evolving demands of consumers.

Finally, the cost-effectiveness of automotive felt fabric cannot be overlooked. In comparison to other materials, felt is relatively inexpensive to produce and install. Its lightweight nature also contributes to overall vehicle efficiency, as lighter materials can lead to better fuel economy and reduced emissions. This balance of affordability and performance makes automotive felt fabric an attractive option for manufacturers aiming to optimize their production processes.

In conclusion, automotive felt fabric serves a multifaceted purpose in vehicle manufacturing, contributing significantly to sound insulation, thermal management, protection of components, and sustainability. As the automotive industry continues to evolve, incorporating innovative materials to enhance vehicle performance and consumer experience will be crucial. Automotive felt fabric stands out as a reliable, versatile, and eco-friendly solution that can help manufacturers meet present and future challenges. Embracing this material not only benefits the vehicles themselves but also ensures that automotive manufacturers remain competitive in an ever-changing marketplace.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024