Jan . 13, 2025 09:41

Back to list

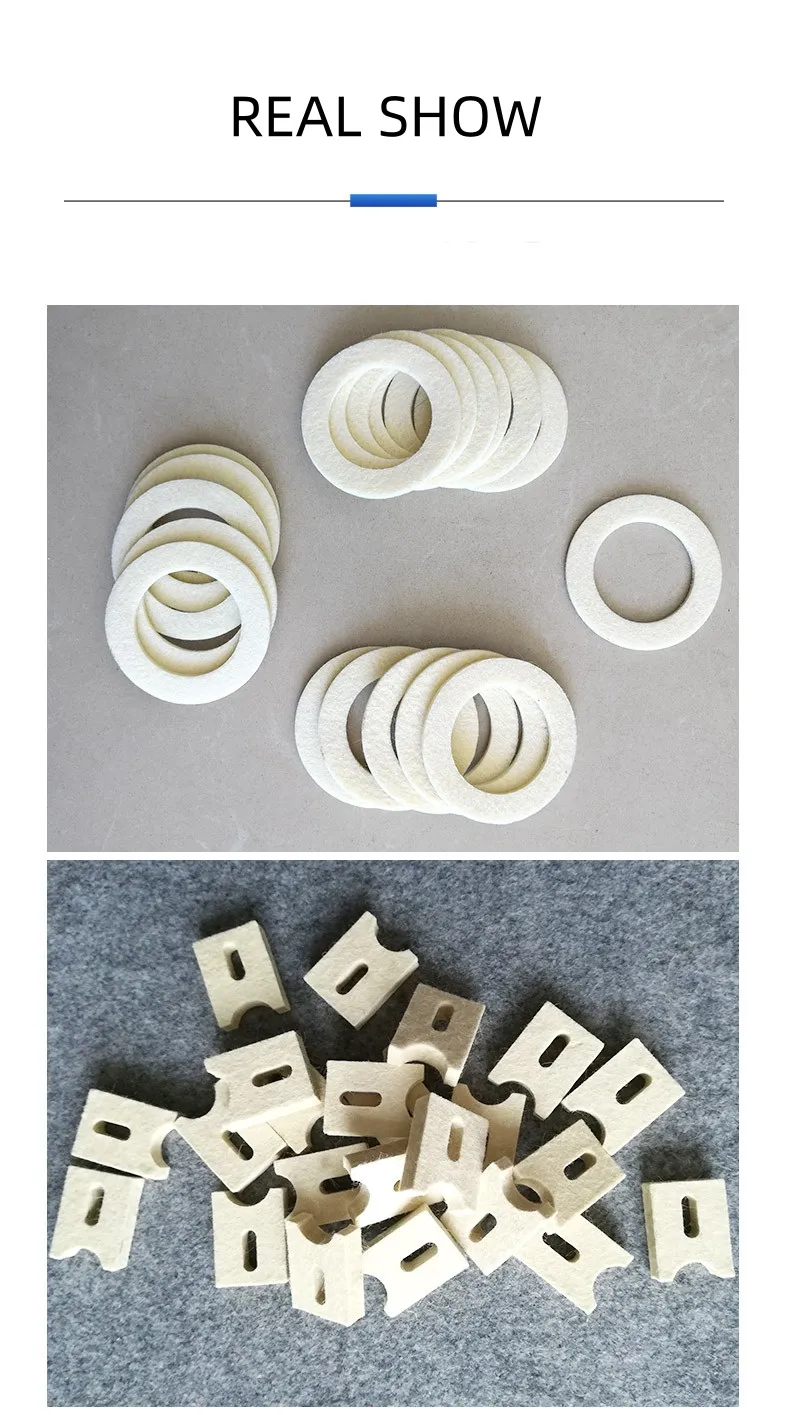

Color Felt Non-Woven Color Felt

The felt process is a fascinating and intricate method used in the creation of a wide array of products, from industrial goods to delicate pieces of art. At its core, felt-making transforms fibers, typically wool or synthetic alternatives, into a dense, durable, and versatile material. This process, though seemingly straightforward, involves a delicate balance of expertise, meticulous attention, and a thorough understanding of each phase to ensure high-quality outcomes.

For those deeply embedded in the craft, the expertise required in controlling the felting conditions—such as temperature and rolling intensity—is second nature. This knowledge ensures that the felt produced meets the specific requirements of the intended application, whether it be for industrial filters, fashion items, or acoustic panels. Such precision and control serve as a testament to the artisans' deep-rooted skill and authority in the field. The final phase of the felt process is finishing, which encompasses various techniques like cutting, dyeing, or treating the felt to add specific properties such as water resistance or fire retardance. In any professional setting, trustworthiness hinges on the maker's ability to finish products to precise specifications. Customers and businesses alike depend on the reliability that skilled artisans provide, assured that each piece of felt will perform as needed across diverse applications. The felt process, when executed by experienced professionals, reflects a harmonic combination of trusted traditional methods and innovative advancements. This synergy not only elevates the quality of the product but also underscores the felt-maker’s position as an authoritative and credible source in the textile industry. As markets continue to evolve with technological advancements, the felt process remains a durable testament to human ingenuity and craftsmanship, continually adapting to new needs while upholding timeless standards of quality.

For those deeply embedded in the craft, the expertise required in controlling the felting conditions—such as temperature and rolling intensity—is second nature. This knowledge ensures that the felt produced meets the specific requirements of the intended application, whether it be for industrial filters, fashion items, or acoustic panels. Such precision and control serve as a testament to the artisans' deep-rooted skill and authority in the field. The final phase of the felt process is finishing, which encompasses various techniques like cutting, dyeing, or treating the felt to add specific properties such as water resistance or fire retardance. In any professional setting, trustworthiness hinges on the maker's ability to finish products to precise specifications. Customers and businesses alike depend on the reliability that skilled artisans provide, assured that each piece of felt will perform as needed across diverse applications. The felt process, when executed by experienced professionals, reflects a harmonic combination of trusted traditional methods and innovative advancements. This synergy not only elevates the quality of the product but also underscores the felt-maker’s position as an authoritative and credible source in the textile industry. As markets continue to evolve with technological advancements, the felt process remains a durable testament to human ingenuity and craftsmanship, continually adapting to new needs while upholding timeless standards of quality.

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024