felt wheel polishing

The Importance of Felt Wheel Polishing in Various Industries

Felt wheel polishing is a crucial process used across various industries, from automotive to jewelry making. It involves the use of felt wheels, which are made from compressed fibers, to polish and finish surfaces to achieve a high degree of shine and smoothness. This polishing method is essential for enhancing the appearance and quality of products, and it also plays a significant role in preparing surfaces for further treatment or assembly.

One of the primary advantages of felt wheel polishing is its ability to produce a fine finish without harsh abrasives. This makes it ideal for delicate materials like metals, plastics, and even glass, where traditional abrasive polishing methods could cause damage or leave scratches. The softness of the felt allows it to conform to the contours of the material being polished, ensuring a uniform finish without compromising the substrate's integrity.

In the automotive industry, felt wheel polishing is often used to refine metal components, such as engine parts, trim, and wheels. After parts have undergone machining or casting, they may exhibit rough surfaces that can lead to performance issues or aesthetic flaws. By applying felt wheel polishing, manufacturers can significantly improve the surface quality, enhancing both the durability and appearance of the components. A shiny and smooth finish not only looks appealing but also minimizes friction, leading to a better-functioning product.

The jewelry industry is another field where felt wheel polishing shines. Jewelers utilize this technique to polish intricate pieces, such as rings and necklaces, ensuring every aspect reflects light beautifully. Felt polishing wheels are used with suitable polishing compounds, enhancing the luster of precious metals and gemstones. This meticulous attention to finishing can make a significant difference in the final product, often determining its market value.

felt wheel polishing

In addition to its applications in the automotive and jewelry sectors, felt wheel polishing is also widely employed in woodworking. Craftsmen often finish wooden surfaces using felt wheels to achieve a smooth, luxurious feel and appearance. The gentle polishing action of the felt allows for a high-gloss finish, highlighting the natural beauty of the wood grain without damaging the material. It's also used to apply finishes like oils or waxes, providing an additional layer of protection while enhancing the wood's visual appeal.

Moreover, felt wheel polishing is integral in the manufacturing of optical components, such as lenses and prisms. In this context, the precision of the polishing process is paramount. Any imperfection on the surface of optical components can detract from their functionality and performance. Therefore, the use of felt wheels, in conjunction with specially formulated polishing compounds, ensures that these components achieve the high levels of clarity and precision necessary for their intended use.

Another vital consideration in the felt wheel polishing process is the choice of polishing compound. Different compounds are formulated for specific materials and desired finishes. For example, a finer compound is often used for achieving a high-gloss finish on metals, while coarser compounds are suitable for initial polishing stages when more aggressive material removal is required. Understanding the compatibility of the felt wheel and polishing compounds is essential for optimizing the polishing process.

While felt wheel polishing is an essential technique in many industries, it also requires proper handling and maintenance of the polishing equipment. Felt wheels should be regularly cleaned and replaced to ensure consistent and effective polishing results. Users should also be trained in the proper techniques for applying pressure and speed to avoid overheating the material being polished, which can lead to warping or burns.

In conclusion, felt wheel polishing is a versatile and indispensable process across multiple sectors. Its ability to achieve high-quality surfaces without damaging the underlying materials makes it a preferred choice for manufacturers and craftsmen alike. As industries continue to seek advancements in finishing techniques, the role of felt wheel polishing is likely to grow, driving innovations in surface preparation and finishing that will benefit products and industries worldwide.

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

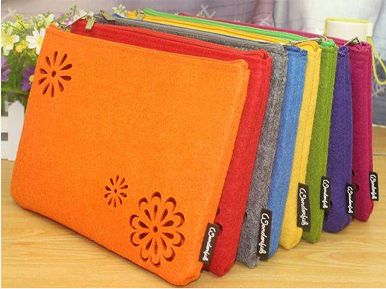

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024