Jan . 10, 2025 09:53

Back to list

Felt sealing ring

Automotive felt fabric plays an integral role in the modern automobile industry. This versatile material is utilized across various aspects of vehicle production, offering both functional and aesthetic advantages. Drawing from years of industry experience, this article delves into the specifics of automotive felt fabric, highlighting its expertise, authoritativeness, and trustworthiness within this sector.

The authoritative standing of automotive felt fabric is further cemented by its widespread adoption by leading car manufacturers. Prominent brands rely on this fabric not only for functional reasons but also for its aesthetic applications. Felt fabric can be found lining the interiors of high-end vehicles, contributing to a luxurious look and feel. Designers leverage its texture and color versatility to match interior themes and enhance overall vehicle design. Trustworthiness in automotive felt fabric is evidenced by rigorous quality standards and testing. Manufacturers must adhere to stringent safety and performance criteria to ensure their products meet industry regulations. This commitment to quality encompasses resistance to flame, durability under varied temperature conditions, and non-toxic material certification. Such standards not only guarantee the safety of end-users but also reinforce trust among automotive companies in the reliability of felt fabric products. To summarize, automotive felt fabric stands out in the automotive industry due to its multifunctional advantages. It enhances vehicle performance through soundproofing and insulation while simultaneously elevating interior aesthetics. Backed by expertise in fabric composition and authoritative usage among leading manufacturers, this material remains a trusted choice in automotive production. The ongoing dedication to quality assurance ensures that automotive felt fabric continues to meet the evolving demands of today's automotive innovations.

The authoritative standing of automotive felt fabric is further cemented by its widespread adoption by leading car manufacturers. Prominent brands rely on this fabric not only for functional reasons but also for its aesthetic applications. Felt fabric can be found lining the interiors of high-end vehicles, contributing to a luxurious look and feel. Designers leverage its texture and color versatility to match interior themes and enhance overall vehicle design. Trustworthiness in automotive felt fabric is evidenced by rigorous quality standards and testing. Manufacturers must adhere to stringent safety and performance criteria to ensure their products meet industry regulations. This commitment to quality encompasses resistance to flame, durability under varied temperature conditions, and non-toxic material certification. Such standards not only guarantee the safety of end-users but also reinforce trust among automotive companies in the reliability of felt fabric products. To summarize, automotive felt fabric stands out in the automotive industry due to its multifunctional advantages. It enhances vehicle performance through soundproofing and insulation while simultaneously elevating interior aesthetics. Backed by expertise in fabric composition and authoritative usage among leading manufacturers, this material remains a trusted choice in automotive production. The ongoing dedication to quality assurance ensures that automotive felt fabric continues to meet the evolving demands of today's automotive innovations.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

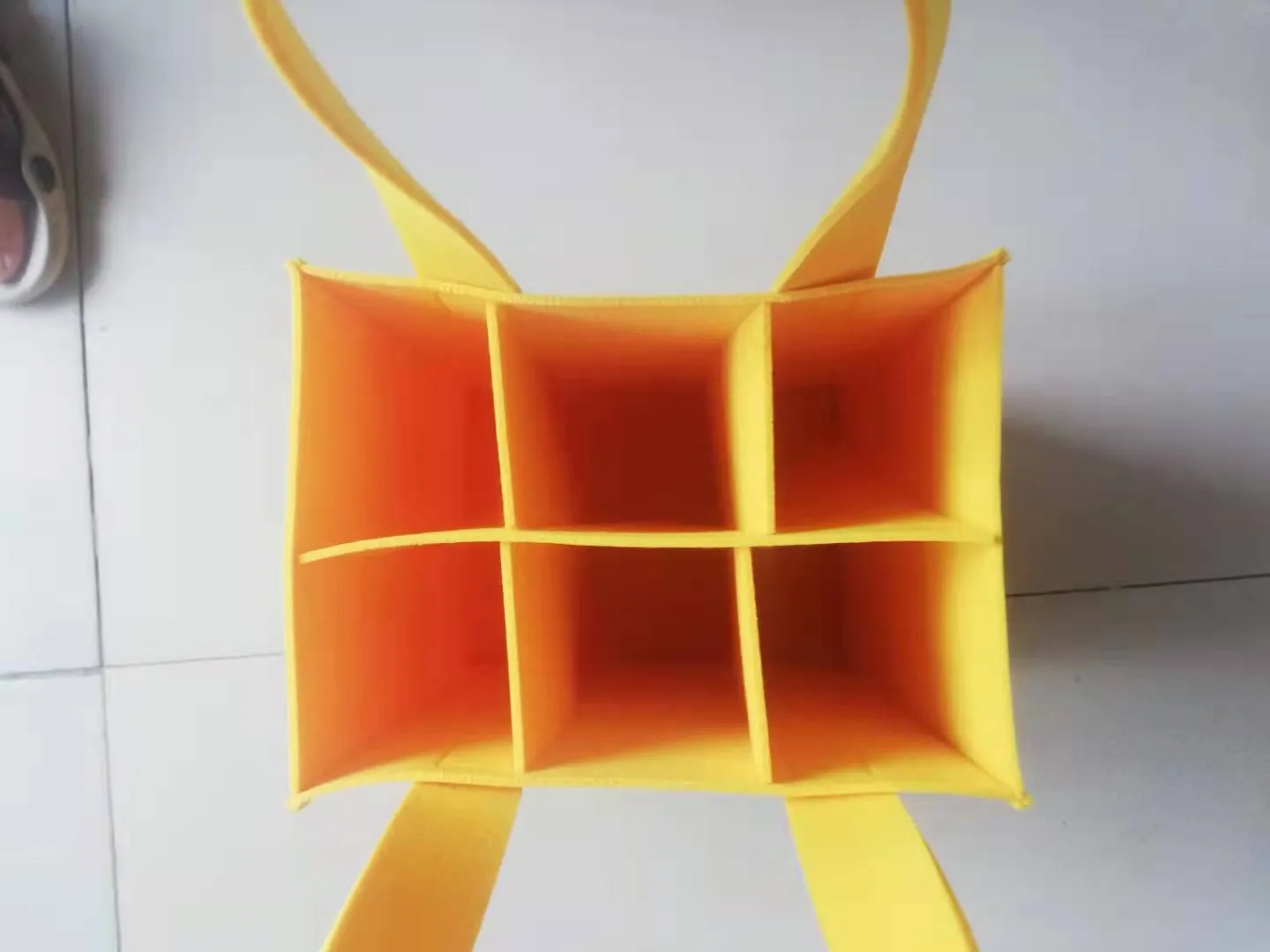

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024