Feb . 03, 2025 04:47

Back to list

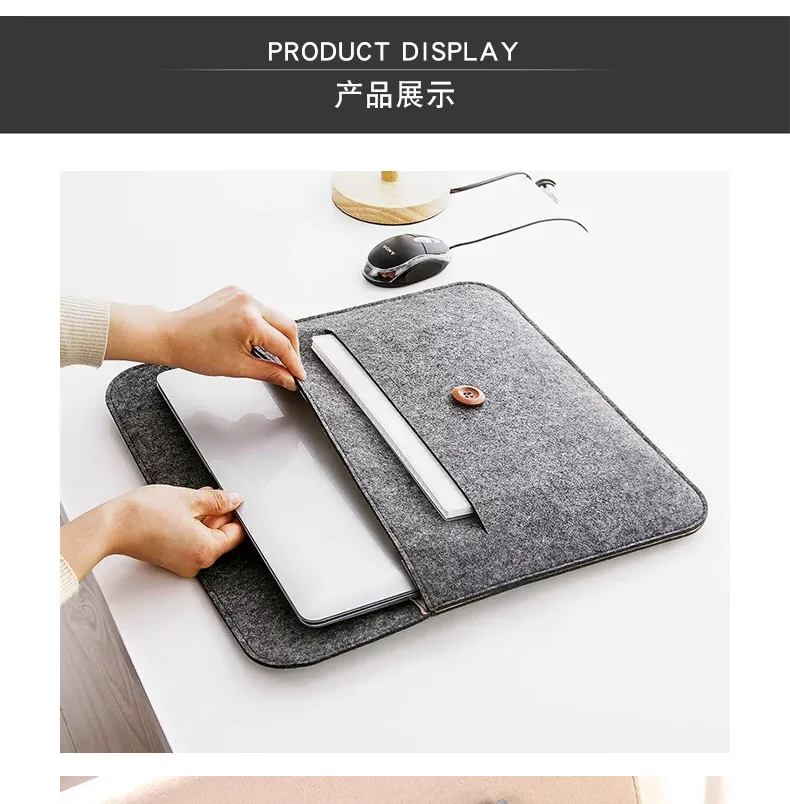

Color Felt Non-Woven Color Felt

Industrial felt has become an indispensable material across various industries, serving as a vital component for numerous applications thanks to its unique properties. From its efficient use in filtration to its role in polishing and cushioning, industrial felt stands out for its durability and versatility. Businesses looking to optimize their manufacturing processes or improve their product offerings recognize the importance of high-quality felt, and understanding what makes it essential can empower decision-making and elevate operational efficiency.

The versatility of industrial felt extends beyond functional purposes to aesthetic applications. It can be dyed in various colors, offering design appeal for creative projects within architecture and interior design industries. Designers utilize colored felt for acoustic panels, room dividers, and decorative wall treatments, balancing form with function by improving sound quality while adding visual interest. When sourcing industrial felt, it’s essential to consider the manufacturer’s expertise and the quality of their offerings. Credibility and experience in producing high-grade felt underscore the reliability of the product. Businesses should look for manufacturers that prioritize sustainable practices, such as using recycled materials or employing environmentally friendly production methods, as this not only aligns with growing environmental standards but also enhances the company’s reputation in increasingly eco-conscious markets. Moreover, partnering with a supplier with a proven track record in meeting industry-specific requirements ensures a match between the product and end-use expectations. Manufacturers offering customization options for felt products can provide tailored solutions that meet precise industry specifications, further enhancing operational effectiveness. In conclusion, purchasing industrial felt involves more than just selecting a material; it demands a strategic approach considering application requirements, supplier reliability, and quality standards. By investing in high-quality felt and partnering with reputable manufacturers, industries can enhance their processes, leading to superior product outcomes and improved business performance.

The versatility of industrial felt extends beyond functional purposes to aesthetic applications. It can be dyed in various colors, offering design appeal for creative projects within architecture and interior design industries. Designers utilize colored felt for acoustic panels, room dividers, and decorative wall treatments, balancing form with function by improving sound quality while adding visual interest. When sourcing industrial felt, it’s essential to consider the manufacturer’s expertise and the quality of their offerings. Credibility and experience in producing high-grade felt underscore the reliability of the product. Businesses should look for manufacturers that prioritize sustainable practices, such as using recycled materials or employing environmentally friendly production methods, as this not only aligns with growing environmental standards but also enhances the company’s reputation in increasingly eco-conscious markets. Moreover, partnering with a supplier with a proven track record in meeting industry-specific requirements ensures a match between the product and end-use expectations. Manufacturers offering customization options for felt products can provide tailored solutions that meet precise industry specifications, further enhancing operational effectiveness. In conclusion, purchasing industrial felt involves more than just selecting a material; it demands a strategic approach considering application requirements, supplier reliability, and quality standards. By investing in high-quality felt and partnering with reputable manufacturers, industries can enhance their processes, leading to superior product outcomes and improved business performance.

Next:

Latest news

-

What Makes Felt a Great Choice?NewsNov.19,2024

-

Total Mixed Ration (TMR) Feed for CattleNewsNov.19,2024

-

The Ultimate Guide for Felt Polishing WheelsNewsNov.19,2024

-

Industrial Felt for Various ApplicationsNewsNov.19,2024

-

Felt Makeup Bags and Inserts BagsNewsNov.19,2024

-

Choosing the Right Hotel TowelsNewsNov.19,2024

-

Your Go-To Guide For Affordable Wholesale Wool FeltsNewsOct.31,2024